wholesale 6 axis machining - manufacturer, supplier, factory

Understanding 6 Axis Machining: 6 axis machining involves a highly advanced CNC (Computer Numerical Control) technology that maneuvers cutting tools across six different axes. This allows for the creation of intricate components and precise shapes in a single setup, enhancing efficiency and accuracy. It's an ideal solution for complex manufacturing tasks, offering superior flexibility in crafting high-quality products.

Product Maintenance and Care Recommendations:

- Regularly clean and lubricate your machinery to ensure optimal performance and longevity. Use appropriate cleaning agents that do not damage the components.

- Conduct routine inspections to identify any wear and tear. Replace parts that show signs of degradation to prevent unexpected downtime.

- Ensure proper calibration of equipment at scheduled intervals to maintain precision in manufacturing processes.

- Provide adequate training for operators to handle the machinery correctly, reducing the risk of operational errors leading to equipment damage.

Environmental Protection and Social Responsibility:

- Incorporate sustainable materials and processes into your manufacturing to minimize environmental impact.

- Implement waste management systems to recycle and dispose of materials responsibly.

- Commit to energy-efficient practices by optimizing machine usage to lower the carbon footprint.

- Engage in community initiatives that support social welfare, enhancing the quality of life for all stakeholders.

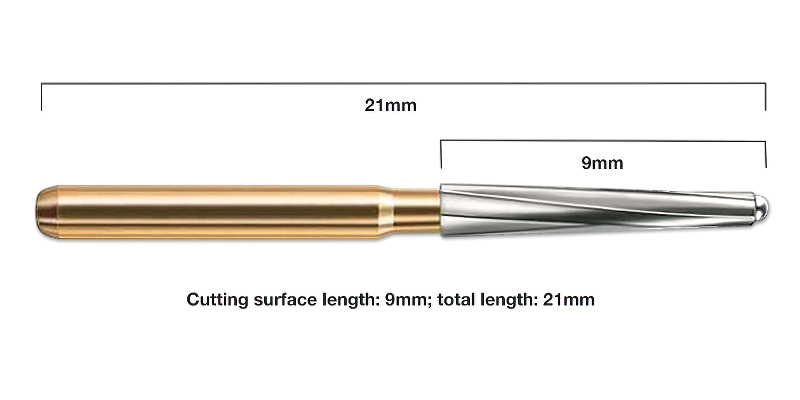

User Hot Search:CNC milling machine for dental bur, tungsten carbide burs in dentistry, 245 bur, chamfer burs.

Related Products

Top Selling Products

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Lithuanian

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese