wholesale bur inverted cone - manufacturer, supplier, factory

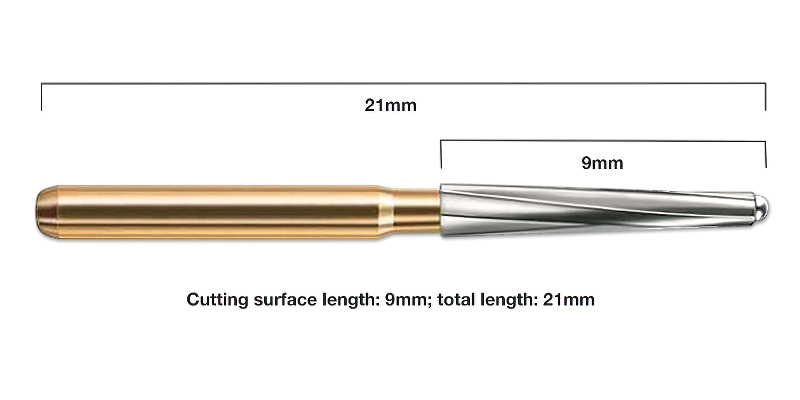

A bur inverted cone is a specialized dental tool used primarily in dentistry for cutting and shaping tooth structures or restorations. With its unique inverted cone shape, it ensures precision in creating undercuts and flattening surfaces for cavity preparations, making it a favorite tool for dental professionals seeking accuracy and efficiency.

Features and Advantages:

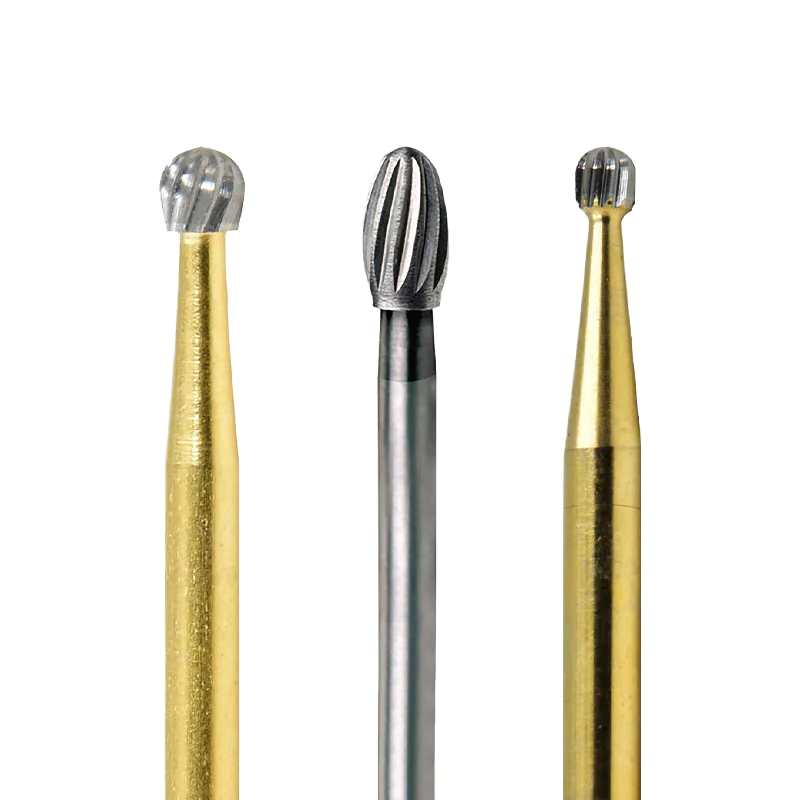

- Precision Engineering: Our bur inverted cones are crafted with cutting-edge technology, ensuring each tool meets the highest standards of precision. This minimizes operator error and maximizes the quality of dental procedures.

- Durable Materials: Made from high-quality, wear-resistant materials, our burs promise longevity and repeated use without compromising on performance, providing excellent value for investment.

- Efficient Design: The unique shape allows for smooth, effortless cutting, reducing procedure times and enhancing patient comfort, thereby improving overall patient satisfaction.

Design Case Introductions:

- Case Study A: Streamlining Workflow

After integrating our bur inverted cones into their practice, Dental Clinic A reported a 25% reduction in procedure time, significantly improving their patient turnover while maintaining high-quality care. - Case Study B: Enhanced Precision

Dentist Dr. Smith experienced improved accuracy in cavity preparations, leading to a noticeable decrease in postoperative complications, thanks to the precision of our inverted cone design. - Case Study C: Cost-Effectiveness

Dental Practice B noted a 30% increase in tool lifespan, resulting in reduced tool replacement costs and reinforcing their choice in our cost-effective, long-lasting solution.

User Hot Search:high precision cnc machining, carbide 702, carbide 245, diamond burs.

Related Products

Top Selling Products

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Lithuanian

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese