wholesale burs for dental - manufacturer, supplier, factory

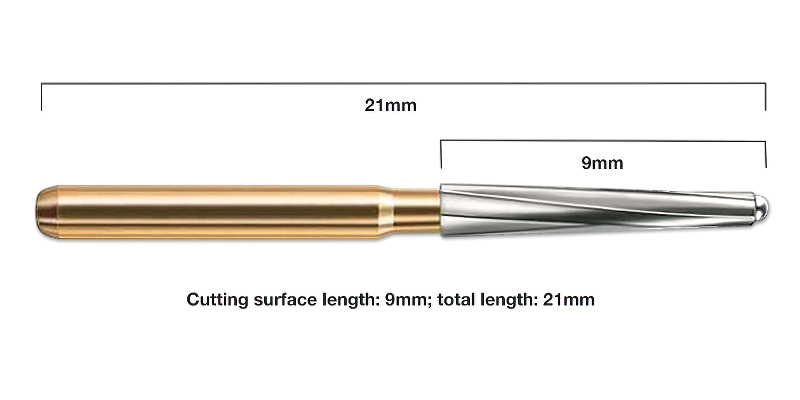

Burs for dental use are essential rotary instruments used in various dental procedures. They are designed to cut, shape, and remove hard tissues, such as teeth and bones, in restorative and surgical operations. Manufactured in multiple shapes and sizes, dental burs accommodate precise cutting needs, ensuring minimal discomfort for patients and enhanced efficiency for dental professionals.

Production Process Description 1: Our burs are manufactured using state-of-the-art CNC machines that ensure precision and consistency in every piece. The high-grade, heat-treated steel core is meticulously crafted to achieve the perfect balance between sharpness and durability, making our burs long-lasting and efficient.

Production Process Description 2: We implement a rigorous quality inspection process that involves laser scanning technology, verifying each bur's dimensions and surface integrity. This step ensures that only the burs meeting stringent industry standards reach our customers, guaranteeing superior performance and reliability.

Advantage 1: Unlike our competitors, who often skip essential post-production inspections, our additional quality control measures ensure you receive only the highest standard burs, translating to improved safety and performance in dental operations.

Advantage 2: While many in the industry compromise on materials to cut costs, we remain committed to using only premium-grade materials. This dedication not only extends the lifespan of our burs but also provides unmatched cutting precision, making your practice more efficient and effective.

User Hot Search:milling precision, dental bur, 330 diamond bur, tool cnc milling.

Related Products

Top Selling Products

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Lithuanian

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese