wholesale burs for dentistry - manufacturer, supplier, factory

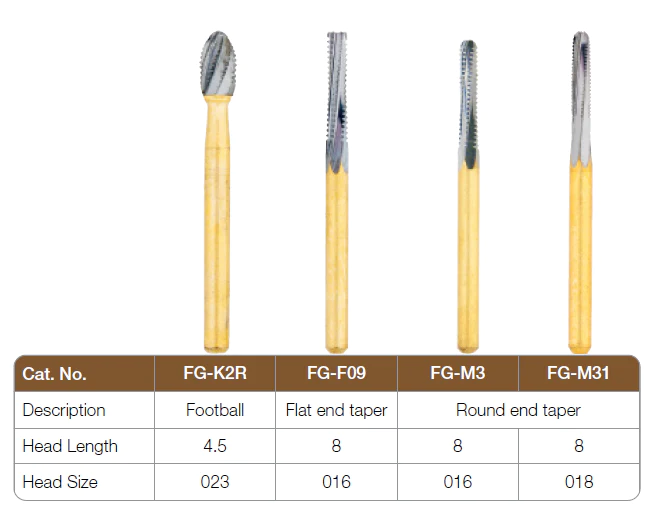

Burs for dentistry are precision instruments used by dental professionals to cut, grind, and remove decay during procedures. Typically made from stainless steel or tungsten carbide, these rotary tools come in various shapes and sizes, allowing for highly precise work in dental restoration and oral surgery.

In recent years, the dental industry has embraced environmental protection and sustainable development, with three key initiatives leading the way. Firstly, many manufacturers are adopting eco-friendly practices, using recyclable materials and reducing waste during production. Secondly, energy-efficient practices are being implemented in factories, decreasing the carbon footprint of dental tool production. Thirdly, there is a push towards developing reusable and long-lasting burs, reducing the need for frequent replacements and minimizing environmental impact.

Two hot topics in the field of dental manufacturing are gaining traction. The first is the integration of biodegradable materials in single-use dental products, which significantly reduces dental waste in landfills. The second is the advancement of 3D printing technology in producing dental burs, offering a customizable, precise, and waste-minimizing alternative to traditional manufacturing.

As dental factories, particularly those specializing in wholesale burs, continue to innovate, these sustainable practices not only contribute to environmental protection but also cater to the growing demand for green products from eco-conscious dental professionals and patients alike.

User Hot Search:contra angle handpiece burs, fg 7901 bur, burs for dentistry, flat end taper bur.

Related Products

Top Selling Products

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Lithuanian

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese