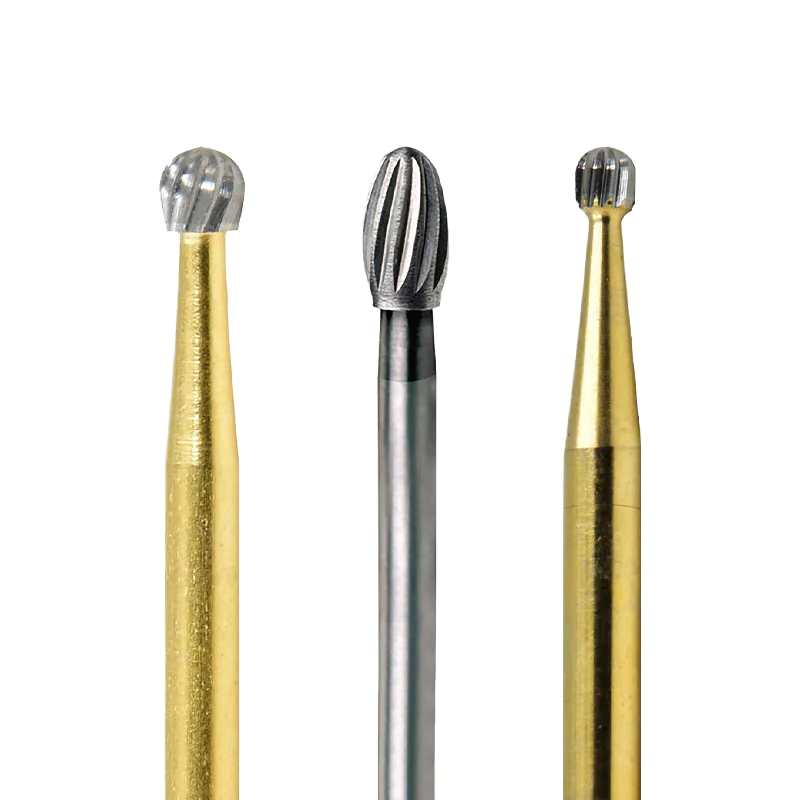

wholesale carbide 330 - manufacturer, supplier, factory

Introduction to Carbide 330: Carbide 330 is a high-grade, durable material widely used in industrial applications, renowned for its exceptional hardness and resistance to wear and corrosion. Typically crafted from tungsten carbide, this material is ideal for crafting precision tools and components that demand longevity and efficiency, making it a staple in manufacturing and machining industries.

Product Maintenance and Care Recommendations:

- Regular Cleaning: To maintain the longevity of Carbide 330 products, ensure they are cleaned regularly. Use a soft cloth and mild detergent to remove any dirt or residue, avoiding harsh chemicals that might affect the carbide's integrity.

- Proper Storage: Store Carbide 330 items in a dry, temperature-controlled environment to prevent any potential corrosion or deformation. Keeping them away from humidity and extreme temperatures will preserve their structural integrity.

FAQs:

- What applications are best suited for Carbide 330?

Carbide 330 is ideal for applications requiring high precision and durability, such as cutting tools, industrial machinery parts, and mold components. - How does Carbide 330 compare to other materials?

Carbide 330 offers superior hardness and wear resistance compared to many other industrial materials, making it an excellent choice for demanding environments and high-stress applications.

User Hot Search:burs for cavity preparation, Saw Grinding, cone bur, cnc mill.

Related Products

Top Selling Products

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Lithuanian

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese