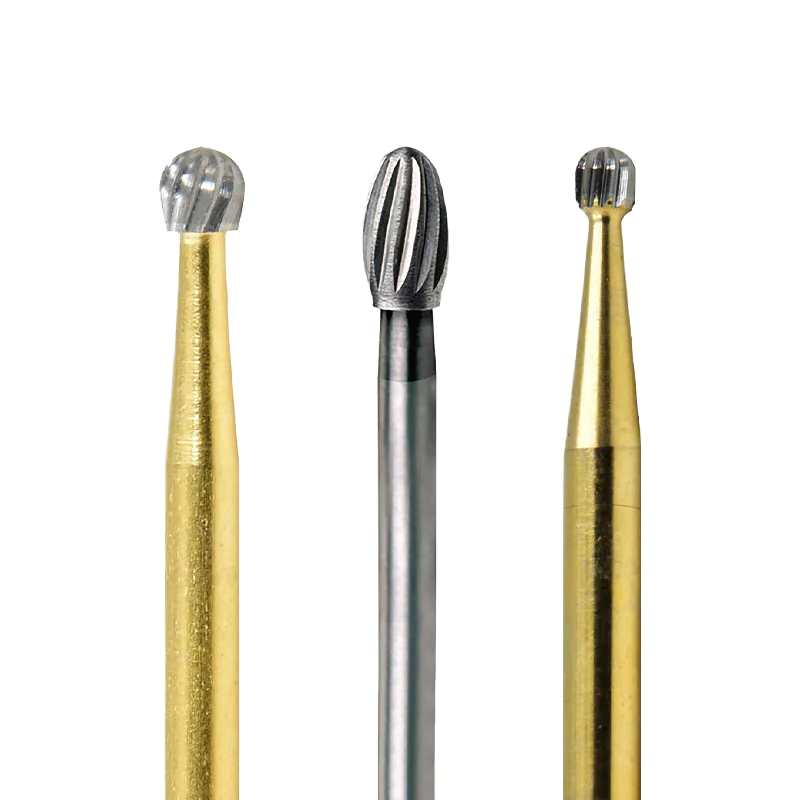

wholesale carbide ball burrs - manufacturer, supplier, factory

Carbide ball burrs are precision tools made from tungsten carbide, known for their hardness and durability. They are widely used in industries for shaping, deburring, and carving materials such as metals, plastics, and wood. These tools are essential in manufacturing sectors that require meticulous surface finishing and material removal.

Industry Dynamics and Trends:

- Technological Advancements: The development of advanced manufacturing technologies, such as CNC machining, is driving the demand for high-quality carbide ball burrs. Precision and efficiency are key, as industries seek to enhance productivity while maintaining superior product standards.

- Global Supply Chain Evolution: The globalization of supply chains has opened up new markets for carbide ball burrs manufacturers. With increased availability of raw materials and advanced logistics, manufacturers can cater to a diverse set of clients across different continents.

Hot Topic Articles:

- The Rise of Carbide Tools in Modern Manufacturing: Explore how the adoption of carbide tools like ball burrs is reshaping manufacturing processes worldwide, emphasizing precision and durability.

- Sustainability in Carbide Production: Discuss the environmental impact of carbide production and how manufacturers are striving to achieve sustainability through innovative practices and recycling initiatives.

- Future-Proofing with High-Performance Tools: Analyze the role of high-performance carbide ball burrs in ensuring industries remain competitive in a rapidly evolving technological landscape.

User Hot Search:bone cutting bur, dental bur, carbide burr 1 4, fg 557.

Related Products

Top Selling Products

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Lithuanian

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese