wholesale carbide bur 330 - manufacturer, supplier, factory

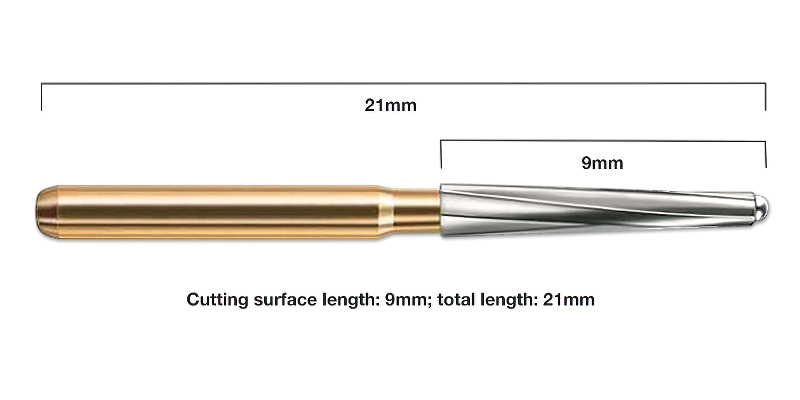

Carbide bur 330 is a cutting tool designed for precision work, commonly used in dental and industrial applications to shape, smooth, and remove material. Known for its durability and efficiency, this specific bur type features a cylindrical shape with a flat end that ensures smooth, controlled cuts, making it an essential tool for professionals demanding high-quality results.

Production Process Description 1: Our carbide bur 330 production starts with the selection of premium carbide material. This is followed by an advanced sintering process, which enhances the tool's hardness and wear resistance. Each bur is meticulously formed using CNC grinding technology, ensuring exceptional precision and uniformity. Finally, every piece undergoes rigorous quality checks to meet the highest industry standards, giving you a product that is both reliable and durable.

Production Process Description 2: The journey of crafting our carbide bur 330 involves state-of-the-art manufacturing techniques. Initially, raw carbide is blended with cobalt, which serves as a binder, to create a robust mixture. The material is then molded and sintered at high temperatures for strength. Precision CNC machines grind the bur to its final specifications, achieving a flawless finish. Each unit is inspected for accuracy and consistency before dispatch, ensuring optimal performance.

Highlights Introductions:

- Unmatched Durability: Our carbide bur 330 is built to last, delivering long-lasting performance even under the toughest conditions, thanks to its superior construction and materials.

- Precision at Its Best: Experience unrivaled accuracy with our meticulously crafted carbide burs, designed to provide smooth operations for all your cutting and shaping needs.

- Reliable Quality: With a commitment to excellence, our carbide bur 330 undergoes extensive quality controls, ensuring each product meets the highest standards for optimal user satisfaction.

User Hot Search:cross cut burs, bur wheel, dental bur machine, aerospace milling.

Related Products

Top Selling Products

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Lithuanian

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese