wholesale carbide bur - manufacturer, supplier, factory

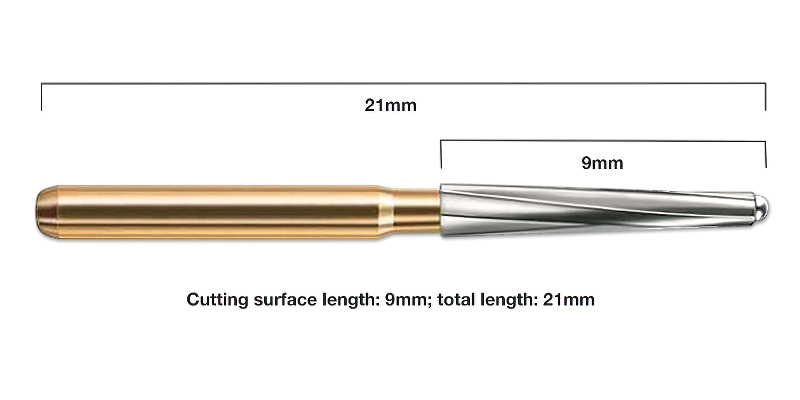

Carbide burs are precision rotary tools used predominantly in dentistry and manufacturing. These tools are constructed from carbide, a durable and hard material that effectively cuts through various surfaces, providing a smooth finish. Carbide burs come in multiple shapes and sizes, designed for different applications like grinding, shaping, and material removal.

Quality Control and Testing Standards

- ISO 9001 Certification: Our carbide burs adhere to the ISO 9001 quality management system. This ensures consistent quality in production, providing our clients with reliable and efficient tools for various applications.

- ANSI/ADA Specification No. 23: All burs meet the American National Standards Institute (ANSI) and American Dental Association (ADA) standards. This guarantees superior performance, safety, and durability in dental procedures.

Application Scenarios

- Dental Practices: Essential for procedures like cavity preparation and crown removal, our carbide burs offer precision and performance critical for modern dentistry.

- Industrial Manufacturing: Whether it's metalworking or wood crafting, carbide burs enhance productivity by delivering precise cuts and extended tool life.

- Jewelry Making: Ideal for shaping and detailing, our burs help jewelers achieve intricate designs with ease and accuracy.

- Automotive Industry: Used in tasks such as engine head porting and gasket surface cleaning, carbide burs are crucial for maintaining vehicle performance.

User Hot Search:bur tapered fissure, typhoon carbide burs, torpedo bur dental, CNC milling machine for dental bur.

Related Products

Top Selling Products

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Lithuanian

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese