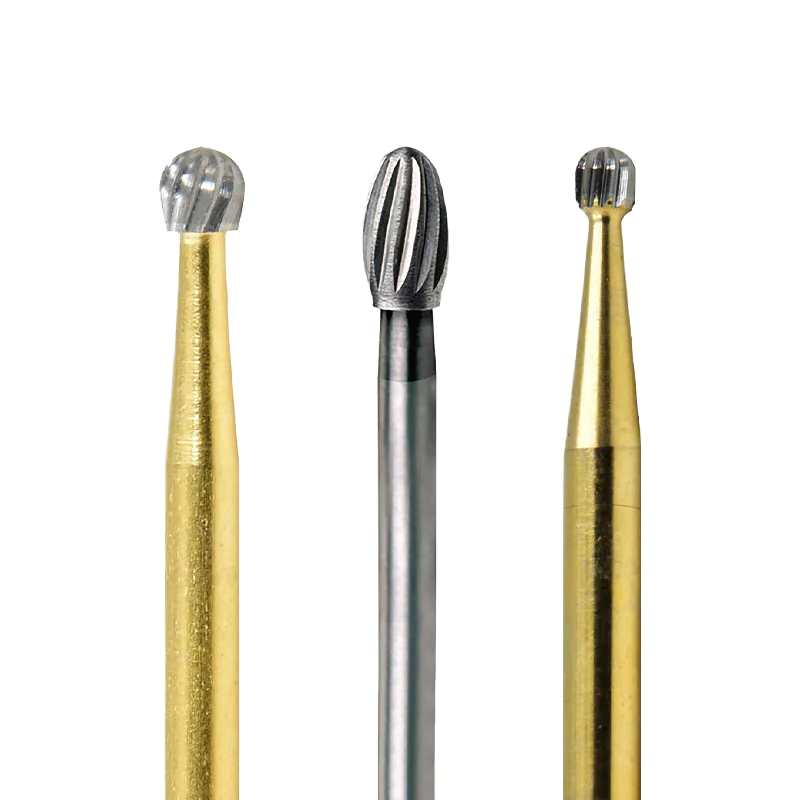

wholesale carbide burr cutter - manufacturer, supplier, factory

Carbide burr cutters are rotary cutting tools used for metalworking, woodworking, and other materials for shaping, grinding, and deburring surfaces. Made from tungsten carbide, these burrs are highly durable and heat-resistant, making them ideal for high-speed applications. A wholesale factory dealing in carbide burr cutters offers efficiency and precision for various industrial needs.

Quality Control and Testing Standards:

- Material Integrity Verification: Each carbide burr cutter is scrutinized before production begins to ensure only top-grade tungsten carbide is used, ensuring long-lasting performance.

- Dimensional Accuracy Testing: Advanced measuring tools are employed to verify each cutter's dimensions meet stringent specifications, ensuring consistent and precise operation in all applications.

- Performance Assessment: Burr cutters undergo rigorous testing on various materials to assess cutting efficiency and durability, guaranteeing they meet industry performance standards.

- Heat Resistance Evaluation: Each tool is tested under high temperatures to ensure thermal stability, maintaining integrity and function during high-speed operations.

Product Maintenance and Care Recommendations:

- Regularly clean carbide burr cutters with a soft brush to remove debris and maintain cutting efficiency.

- Avoid using excessive force during operation to extend the cutter's lifespan and prevent breakage.

- Store in a dry, cool place to prevent any rust or wear, ensuring long-term use.

- Periodically inspect for wear and replace when any signs of damage are noted to maintain optimal performance.

User Hot Search:557 bur, bur teeth, dental bur 557, cnc micro milling.

Related Products

Top Selling Products

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Lithuanian

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese