wholesale carbide burrs for die grinder - manufacturer, supplier, factory

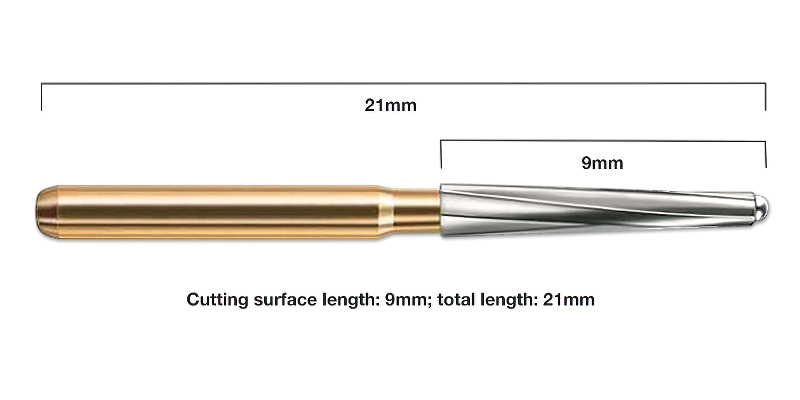

Carbide burrs are precision rotary tools used in die grinders for cutting, shaping, grinding, and removing material from various substrates such as metal, wood, and plastic. Made from tungsten carbide, these burrs are renowned for their durability and efficiency, making them indispensable in industries like automotive, aerospace, and metal fabrication.

Pre-sales Consultation and Solution Customization

- Tailored Recommendations: Our experienced sales team provides personalized consultations to understand your specific needs, ensuring you receive the most suitable carbide burrs for your applications.

- Sample Testing: We offer sample burr testing to guarantee the product meets your operational standards and expectations before committing to a bulk purchase.

- Custom Solutions: Should your needs demand, we offer customization services to adapt our carbide burr designs to fit your unique operational requirements and enhance performance efficiency.

Product Maintenance and Care Recommendations

- Regular Inspection: Frequently check your carbide burrs for visible signs of wear and tear to ensure optimal performance and longevity.

- Proper Cleaning: Clean your burrs with a soft brush or compressed air after each use to remove residual materials and prevent clogging.

- Storage Practices: Store carbide burrs in a dry, safe environment to protect against corrosion and damage, using protective cases if possible to maintain their sharpness and reliability.

User Hot Search:859 surgical bur, flame shaped finishing bur, 245 carbide bur, flat fissure bur.

Related Products

Top Selling Products

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Lithuanian

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese