wholesale carbide burs in dentistry - manufacturer, supplier, factory

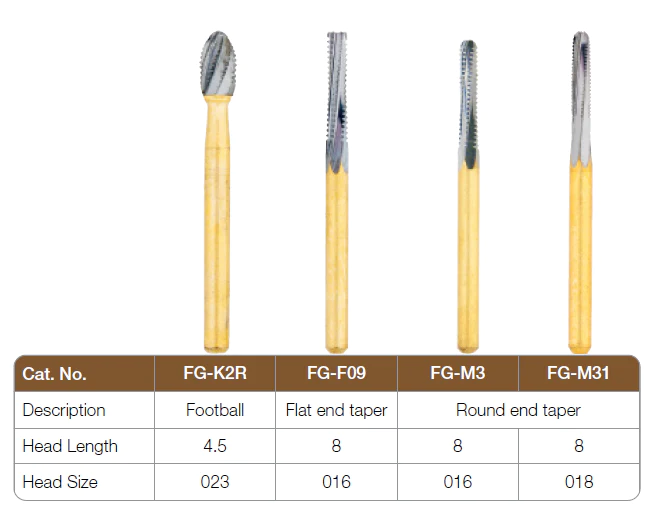

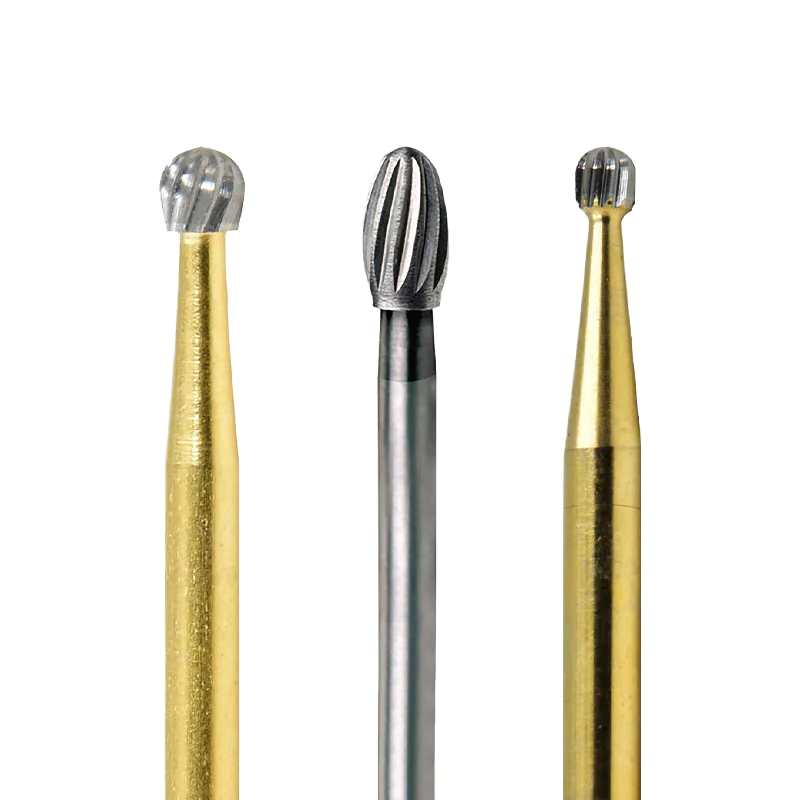

Carbide burs are essential rotary tools used in dentistry for cutting, shaping, and contouring tooth structure and dental materials. Made from high-quality tungsten carbide, these burs offer precision and durability for various dental procedures, such as cavity preparation and crown removal.

Global Sales Network and Support:

- Extensive Distribution: Our carbide burs reach dental professionals worldwide through an extensive network of distributors, ensuring availability and timely delivery. We collaborate with trusted partners to maintain a consistent supply chain.

- Customer-Centric Approach: Our dedicated sales team provides personalized support to address specific customer needs, offering expert guidance and solutions. We prioritize building long-term relationships with our clients.

- Comprehensive Training: We offer comprehensive training programs and resources to support our distributors and dental professionals. By facilitating product knowledge and best practices, we ensure the optimal use of our carbide burs.

Production Process Descriptions:

- High-Quality Raw Materials: We use premium tungsten carbide for manufacturing. This ensures that our burs provide exceptional hardness and efficiency.

- Precision Engineering: Our advanced machinery and skilled technicians craft each bur with meticulous attention to detail, resulting in accurate and effective cutting performance.

- Stringent Quality Control: Every carbide bur undergoes rigorous testing and quality assurance processes to meet the highest industry standards, guaranteeing reliability and safety.

- Innovative Design: Our research and development team continuously innovates to enhance the design of our burs, optimizing them for performance and ease of use in dental procedures.

User Hot Search:tapered fissure bur, CNC milling machine for tools, carbide finishing bur, burs for dental.

Related Products

Top Selling Products

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Lithuanian

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese