wholesale carbide rotary burs - manufacturer, supplier, factory

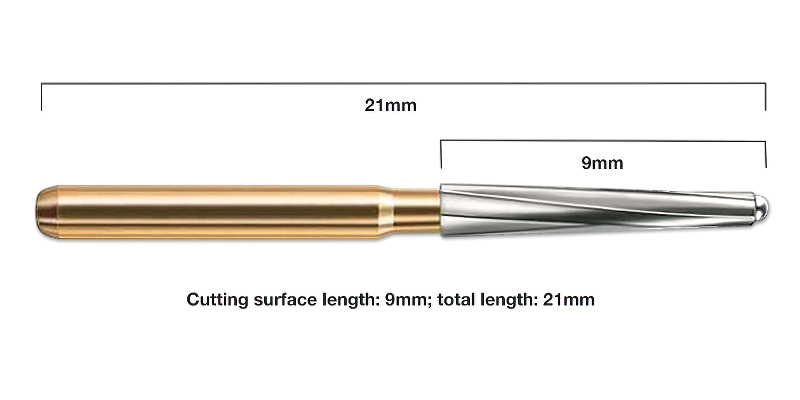

Carbide rotary burs are precision tools used in metalworking and other industries for shaping, cutting, and grinding hard materials. Made from tungsten carbide, these burs are renowned for their durability and efficiency. Unlike traditional steel tools, carbide rotary burs retain their sharpness and are highly resistant to wear and tear, making them ideal for industrial applications.

Environmental Protection and Sustainable Development Initiatives:

- Eco-friendly Manufacturing: We implement eco-conscious practices in our production process, minimizing waste and conserving energy, contributing to a smaller carbon footprint.

- Recycling Programs: We recycle scrap materials from our manufacturing, ensuring resources are reused and reducing environmental impact.

- Sustainable Sourcing: Our materials are sourced from environmentally responsible suppliers who prioritize sustainable practices, helping preserve natural resources.

Product Maintenance and Care Recommendations:

- Routine Cleaning: Clean carbide rotary burs regularly with a soft brush to remove debris and prolong their life.

- Proper Storage: Store in a dry, organized space to prevent damage and rusting of the burs.

- Usage Guidelines: Follow recommended speeds and applications to prevent premature wear or damage, ensuring optimal performance.

- Regular Inspection: Inspect burs regularly for signs of wear or damage, and replace promptly to maintain the quality of work.

User Hot Search:lindemann bur dental, CNC Blade Grinders, carbide amalgam bur, carbide flame bur.

Related Products

Top Selling Products

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Lithuanian

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese