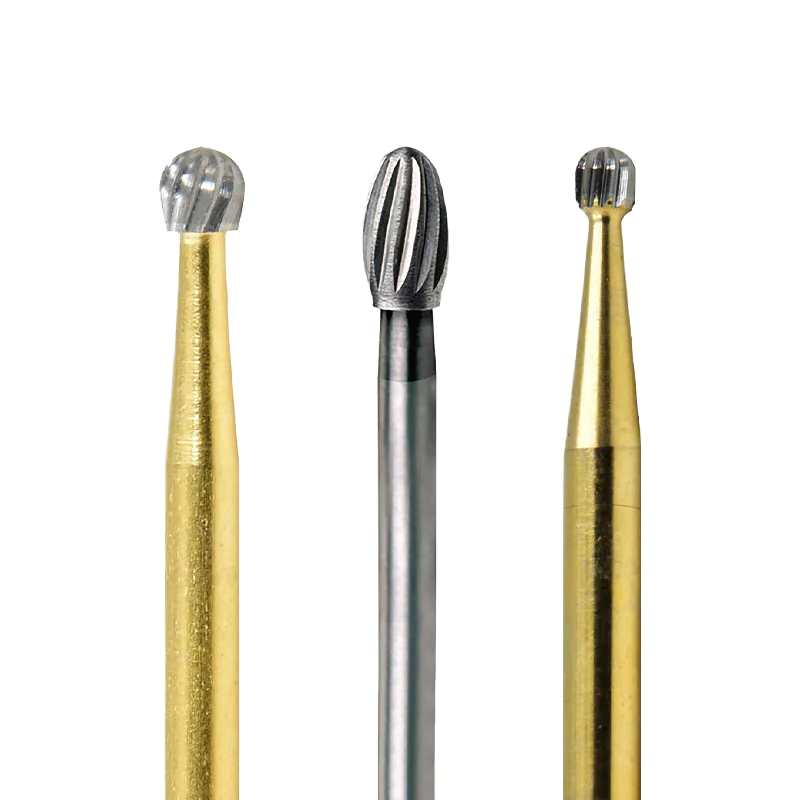

Carving burs are precision tools used in various industries, particularly in woodworking and metalworking. These small, rotary instruments have a bur or cutting head made from durable materials that are mounted on a shank. Carving burs are designed to help artisans and manufacturers cut, shape, and finish materials with intricate detail and accuracy.

Production Process Description 1: Our carving burs are produced using an advanced CNC grinding process. This ensures each bur is manufactured to exacting standards, providing consistent performance. The raw materials, such as tungsten carbide, are selected for their durability and strength, enabling the burs to withstand rigorous use. The process culminates in a high-precision inspection to guarantee quality.

Production Process Description 2: The second stage in creating our carving burs involves a multi-step heat treatment process. This enhances the hardness and toughness of the bur tips, ensuring longevity. After heat treatment, each bur undergoes a rigorous quality check, focusing on dimensional accuracy and surface finish to meet the demands of professional artisans.

Design Case Introduction 1: Our design team recently collaborated with a prominent wood sculptor to develop a custom set of carving burs. Tailored to the artist’s needs, these burs offer unique cutting angles and specific geometries, facilitating the creation of intricate designs and textures while maintaining ease of use.

Design Case Introduction 2: In a project with a leading dental instrument manufacturer, we designed carving burs specifically for precision work in dental laboratories. Emphasizing ergonomic design, these burs provide exceptional control and comfort, which is crucial for dental professionals performing delicate tasks.

Design Case Introduction 3: Our collaboration with an aerospace component supplier led to the development of specialized carving burs that cater to high-strength material applications. These custom-designed burs enhance efficiency by significantly reducing machining time, showcasing our ability to innovate and meet industry-specific needs.