wholesale CNC Grinding machine for dental bur - manufacturer, supplier, factory

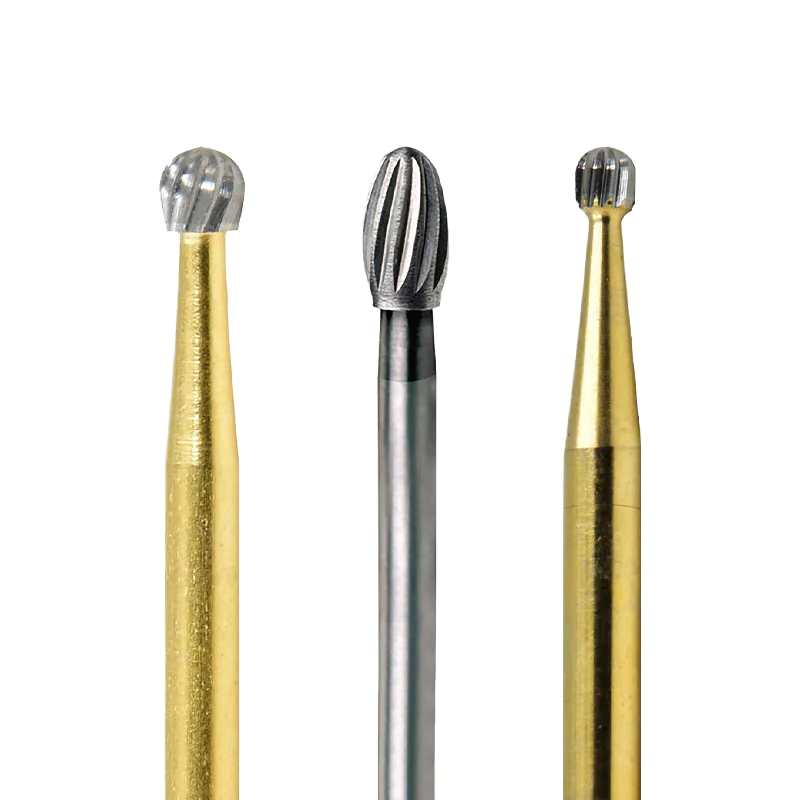

A CNC Grinding machine for dental bur is a specialized piece of equipment designed to manufacture precision dental burs. These machines utilize computerized numerical control (CNC) technology to grind and shape metal into the intricate geometries required for dental tools, ensuring high accuracy, efficiency, and consistency in mass production for dental institutions and tool manufacturers.

FAQ1: What are the benefits of using a CNC Grinding machine for dental bur manufacturing?

The primary benefits include enhanced precision and repeatability, reduced production time, and the ability to produce complex shapes with minimal manual intervention. By automating the grinding process, manufacturers can ensure a consistently high-quality product while significantly increasing their production capacity.

FAQ2: How does CNC technology enhance the manufacturing of dental burs?

CNC technology allows for precise control over the grinding process, enabling the creation of intricate designs and consistent quality across large production runs. This technology also facilitates quick adjustments to designs and quicker changeovers between different product types, enhancing flexibility and reducing downtime.

FAQ3: What should a manufacturer consider when selecting a CNC Grinding machine for dental burs?

Key considerations include the machine’s precision capabilities, speed, ease of use, and flexibility in accommodating various designs. Additionally, investing in a machine with a robust support network is crucial to ensure ongoing maintenance and troubleshooting support.

FAQ4: How does CNC Grinding affect the cost-efficiency of dental bur production?

While the initial investment in a CNC Grinding machine can be substantial, the long-term savings in labor costs, reduced waste, and increased production speeds often result in a positive return on investment. Furthermore, the consistent quality of products reduces the need for rework, thereby enhancing overall profitability.

User Hot Search:carbide bur, burs for dental, lindemann burs, diamond and carbide burs.

Related Products

Top Selling Products

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Lithuanian

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese