wholesale CNC Grinding machine for saw - manufacturer, supplier, factory

A CNC Grinding Machine for saws is an advanced, computer-controlled device used in metalworking and woodworking to precisely grind, sharpen, and polish saw blades. Utilizing computer numerically controlled (CNC) technology, these machines offer unparalleled precision, efficiency, and consistency, ensuring saw blades maintain sharpness, longevity, and optimal performance.

To ensure your CNC Grinding Machine remains in peak condition, consider these maintenance and care recommendations:

- Regular Cleaning: After each use, clean the machine thoroughly to remove sawdust, metal shavings, and any other debris that may accumulate. This helps prevent clogging and extends the life of both the machine and the saw blades.

- Lubrication: Apply appropriate lubricant to all moving parts as per the manufacturer's instructions. This reduces wear and tear, minimizes friction, and ensures smooth operation.

- Routine Inspection: Regularly inspect the machine for any signs of wear, damage, or misalignment. Early detection of issues can prevent costly repairs and downtime.

Here are three key highlights of the CNC Grinding Machine for your saw factory:

- High Precision and Accuracy: CNC technology guarantees extremely accurate and consistent sharpening of saw blades, leading to superior cutting performance and reduced material wastage.

- Increased Productivity: With automated operations, these machines significantly reduce manual labor, allowing for faster processing times and increased factory output.

- Versatility: Capable of handling a variety of blade types and sizes, CNC Grinding Machines provide flexibility to adapt to different manufacturing needs, enhancing operational efficiency in your facility.

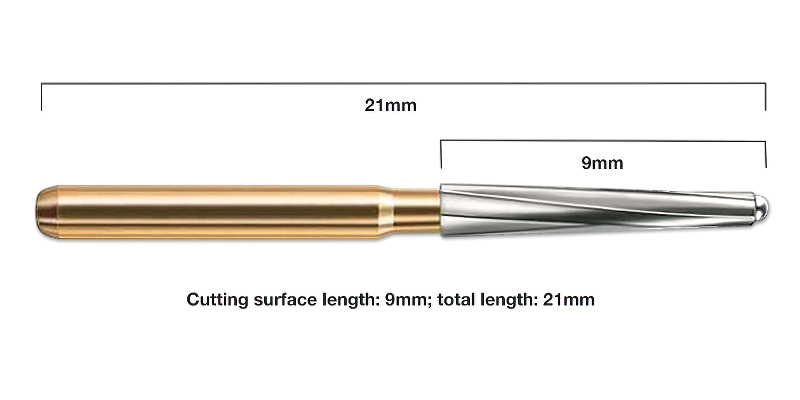

User Hot Search:bone cutting burs dental, 330 carbide bur, surgical burs for straight handpiece, surgical length burs.

Related Products

Top Selling Products

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Lithuanian

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese