wholesale CNC Grinding machine for saw - manufacturer, supplier, factory

Understanding CNC Grinding Machines for Saw Factories

CNC Grinding Machines are precision tools used in saw factories to sharpen and refine saw blades. These machines use computer numerical control (CNC) technology to ensure accuracy and efficiency, reducing manual labor and maximizing productivity. By maintaining sharp and precise saw blades, these machines play a crucial role in ensuring optimal cutting performance and longevity of the blades.

Environmental Protection Initiatives

- Reduced Material Waste: Our CNC Grinding Machines minimize material waste by ensuring precise grinding operations, leading to less discarded material and contributing to a more sustainable production environment. This results in a reduced carbon footprint compared to traditional grinding methods.

- Energy Efficiency: Our machines are designed with energy conservation in mind, incorporating the latest technology to significantly reduce energy consumption. This not only lowers operational costs but also supports global efforts to reduce energy usage and greenhouse gas emissions.

Sustainable Development Advantages

- Advanced Filtration Systems: Our machines feature state-of-the-art filtration systems that effectively capture grinding dust and particles, ensuring a cleaner work environment and protecting air quality in the factory. This surpasses peers who may not prioritize efficient dust management.

- Durability and Longevity: Built with high-quality materials, our CNC Grinding Machines are designed to last longer, reducing the need for frequent replacements. This durability leads to fewer resources used over time, enhancing sustainability compared to competitors’ products.

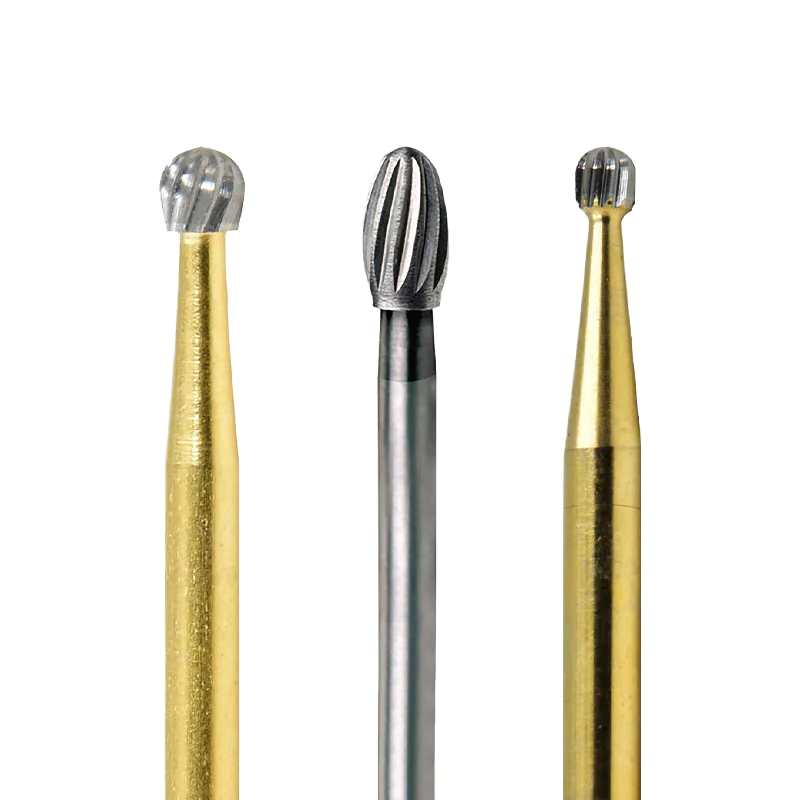

User Hot Search:cnc machine milling machine, bur sets, interdental bur, contra angle handpiece burs.

Related Products

Top Selling Products

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Lithuanian

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese