wholesale cnc milling cost - manufacturer, supplier, factory

CNC milling cost refers to the expenses associated with the computer-controlled process of cutting and shaping materials using a rotating tool. This includes machine operation, tooling, labor, and material costs. As a wholesale CNC milling cost supplier, we aim to provide competitive pricing while maintaining the highest quality standards in the industry.

Environmental Protection and Sustainable Development Initiatives:

- We prioritize the use of eco-friendly materials and processes to minimize our carbon footprint, ensuring a greener production cycle. By reducing waste and optimizing energy consumption, we contribute to sustainable development and promote environmental well-being.

- Our commitment to sustainability extends beyond production. We actively engage in tree-planting initiatives and collaborate with organizations dedicated to restoring natural habitats. These efforts help offset our environmental impact and promote biodiversity.

Product Maintenance and Care Recommendations:

- To ensure the longevity and optimal performance of CNC milled products, regular maintenance is essential. Clean the tools and components after each use, and perform routine inspections for wear and tear.

- Store CNC milled products in a dry, temperature-controlled environment to prevent damage. Ensure that all moving parts are adequately lubricated to maintain smooth operation and prevent rust.

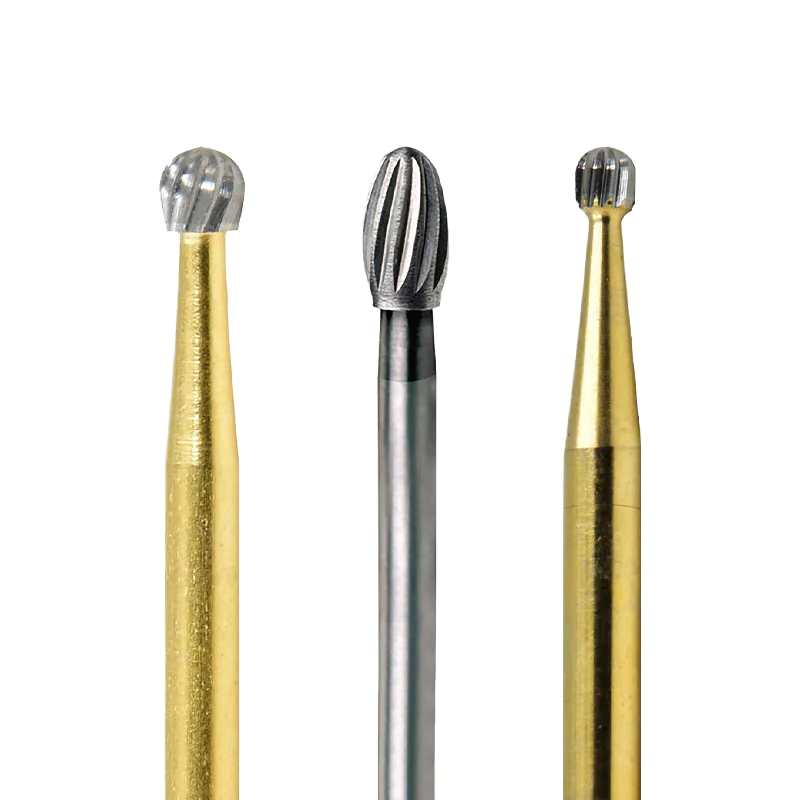

User Hot Search:slow speed round bur, carbide bur, tapered fissure dental burs, fg carbide burs.

Related Products

Top Selling Products

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Lithuanian

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese