wholesale cnc milling machine - manufacturer, supplier, factory

Understanding CNC Milling Machines: CNC (Computer Numerical Control) milling machines are advanced manufacturing tools used for cutting various materials with high precision. These machines utilize computer guidance to control the movement of cutting tools, enabling complex shapes and designs to be produced efficiently and consistently. Their versatility and accuracy make them indispensable in numerous industrial applications.

Production Process Descriptions:

1. Design Phase: The production process begins with the design phase, where the CAD (Computer-Aided Design) software is used to create detailed blueprints of the parts to be manufactured. This digital design is then translated into a language the CNC milling machine can interpret, ensuring the accurate execution of intricate designs.

2. Material Selection: Selecting the right material is crucial for the success of the CNC milling process. Factors such as strength, durability, and thermal properties are considered to choose the best material. Common choices include metals like aluminum and steel, as well as plastics and composites, ensuring the final product meets specified requirements.

3. Machining and Quality Control: The machining phase involves the CNC milling machine following programmed instructions to cut and shape the material. Post-machining, each product undergoes rigorous quality control checks to ensure it meets the outlined specifications. Advanced measurement tools are used to maintain high standards of precision and quality.

Hot Topic Articles:

The Demand Surge in CNC Milling Machines: As industries strive for higher productivity and precision, the demand for CNC milling machines is surging. These machines are revolutionizing manufacturing by offering unparalleled accuracy and efficiency, which translates into lower costs and faster production cycles. This growing trend is reshaping the landscape of industrial manufacturing across the globe.

Sustainability in CNC Milling: As sustainability becomes a priority, CNC milling machine factories are adopting greener practices. By optimizing energy consumption and reducing waste through precision cutting, they are minimizing environmental impact. Additionally, advancements in recyclable materials and eco-friendly lubricants are further promoting sustainable manufacturing processes, aligning with global environmental goals.

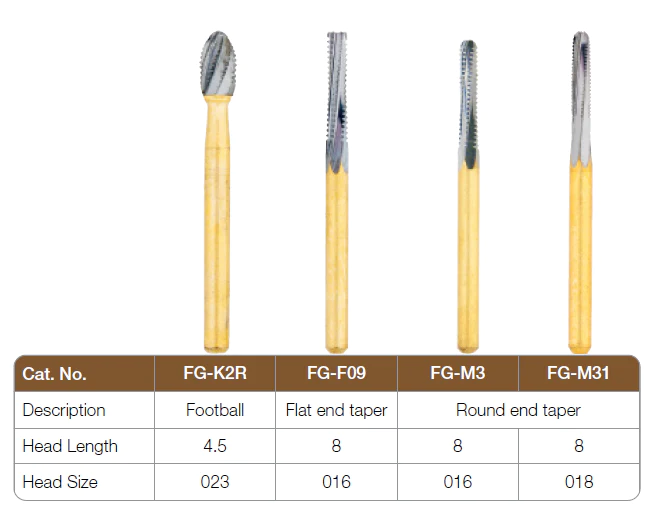

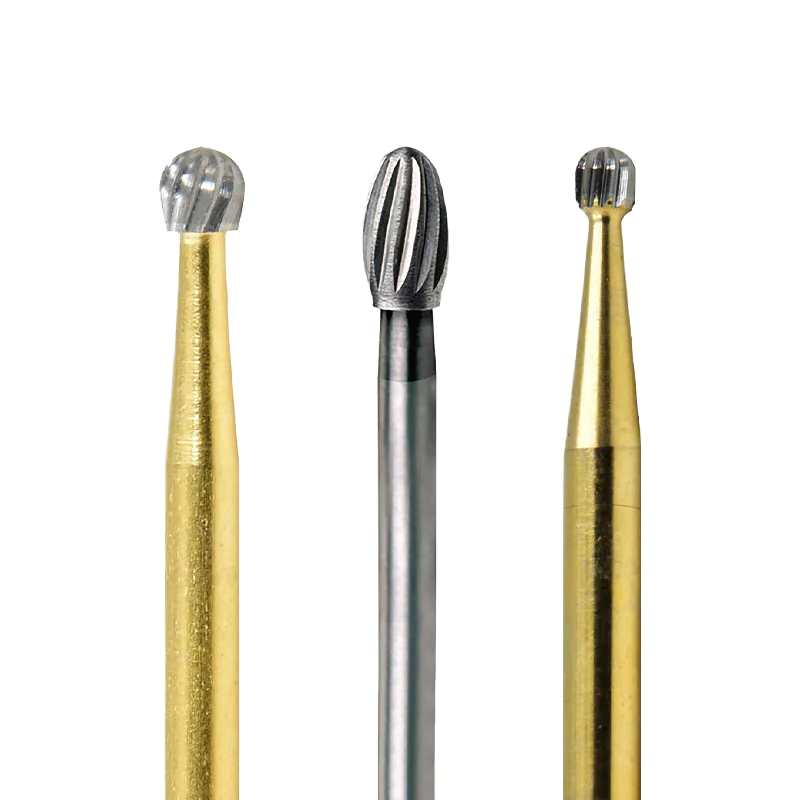

User Hot Search:245 bur, carbide ball burrs, flame bur dental, CNC milling machine for tools.

Related Products

Top Selling Products

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Lithuanian

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese