wholesale cnc milling machine - manufacturer, supplier, factory

CNC milling machines are precision-driven devices used to shape metal and other solid materials by removing material using rotating multi-point cutting tools. These machines are computer-controlled, enabling high accuracy and repeatability in complex manufacturing tasks, making them indispensable in modern production environments.

Pre-sales Consultation

Our team of experts offers pre-sales consultations to understand your specific manufacturing needs and guide you in selecting the right CNC milling machine from our extensive range. We focus on performance, cost-efficiency, and scalability to meet your business objectives effectively.

Solution Customization

We provide tailored solutions to ensure that our CNC milling machines perfectly align with your production requirements. From software integration to component adjustments, our customization capabilities ensure seamless operation and optimized productivity for your manufacturing processes.

Revolutionizing Manufacturing: The Future of CNC Milling

The advent of CNC milling has revolutionized manufacturing, allowing for unrivaled precision and efficiency. As technology continues to evolve, the integration of AI and IoT in CNC milling machines promises to enhance capabilities, offering remarkable advancements in automation and data-driven production.

Choosing the Right CNC Milling Machine for Your Needs

When selecting a CNC milling machine, it's essential to consider factors such as material compatibility, machine size, and the complexity of tasks. Our comprehensive guide helps you navigate these considerations, ensuring your choice enhances operational efficiency and meets production goals.

Unlocking Potential: CNC Milling in Advancing Industries

Industries such as aerospace, automotive, and medical devices leverage CNC milling for its precision, speed, and flexibility. Our machines play a critical role in pushing the boundaries of innovation, enabling the creation of intricate components that meet stringent industry standards.

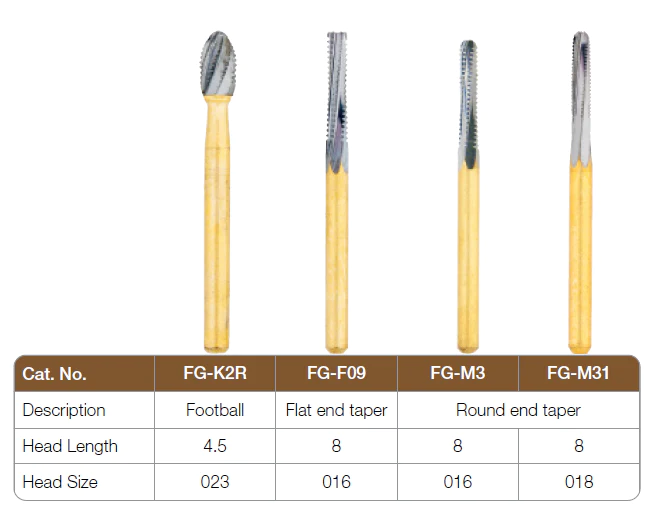

User Hot Search:703 surgical bur, fissure bur, high speed carbide burs, lab burs.

Related Products

Top Selling Products

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Lithuanian

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese