wholesale cross cut burs - manufacturer, supplier, factory

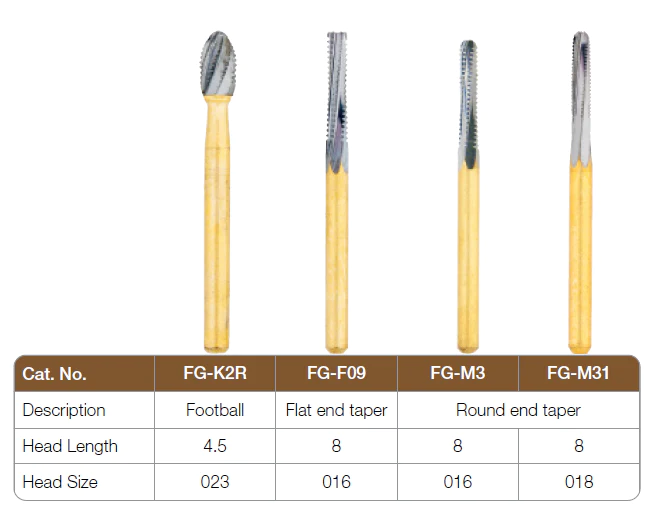

Cross cut burs are precision instruments used in dentistry and various industrial applications to cut and shape materials. Characterized by their intricate cross-patterned cutting edges, they provide enhanced cutting efficiency and smoother finishes, making them essential for procedures that require precise material removal and shaping.

FAQs

What materials can cross cut burs be used on?

Cross cut burs can be used on a range of materials including metals, ceramics, plastics, and dental hard tissues, allowing versatility in both medical and industrial settings.

How can I ensure the longevity of my cross cut burs?

To ensure the longevity of your cross cut burs, it is crucial to follow proper cleaning, sterilization, and storage protocols. Regular inspection and timely replacement of worn burs also help maintain their effectiveness and precision.

Innovation and R&D

Our factory invests heavily in research and development to push the boundaries of cross cut burs technology. By employing advanced materials and coating techniques, we enhance durability and cutting precision, ensuring optimal performance in all applications.

We prioritize sustainable manufacturing processes, aiming to reduce waste and energy consumption. Our R&D team is continuously working on eco-friendly solutions, developing burs that are not only high-performing but also environmentally responsible.

Innovation drives our operations, with feedback loops from clients integrated into our R&D efforts. This collaborative approach ensures we remain at the forefront of industry advancements, delivering products that meet the evolving needs of our customers.

User Hot Search:fg 7901 bur, CNC SAW BLADE SHARPENING MACHINE, carbide die grinder burrs, saw grinding machine.

Related Products

Top Selling Products

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Lithuanian

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese