wholesale dental tungsten carbide burs - manufacturer, supplier, factory

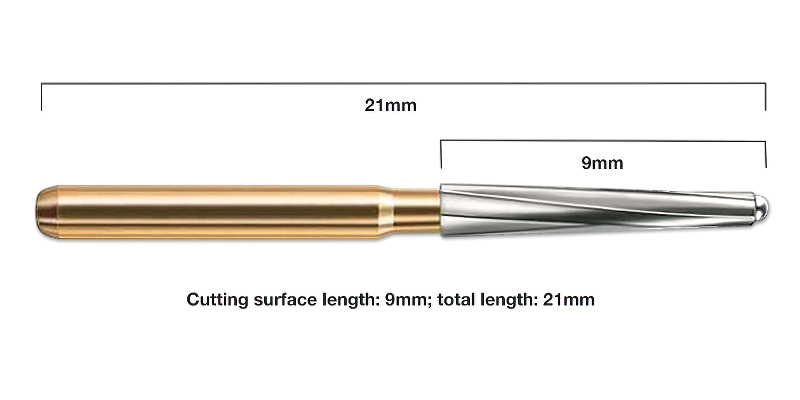

What are Dental Tungsten Carbide Burs? Dental tungsten carbide burs are high-precision rotary instruments used in dentistry for shaping, cutting, and polishing various dental materials. Made from tungsten carbide, a hard and durable material, these burs ensure quick and efficient performance, providing dentists with a reliable tool for patient care.

Product Maintenance and Care Recommendations:

- Proper Cleaning: After each use, clean the burs with an ultrasonic cleaner or by manually scrubbing with a brush under running water. This helps remove debris and prevents build-up that could impede performance. Follow cleaning with sterilization in an autoclave to ensure the highest hygiene standards.

- Safe Storage: Store the burs in a protective holder or sterilization cassette to avoid damage. Keeping them organized reduces the risk of dulling or chipping, and extends the lifespan of your burs.

Production Process Descriptions:

- Material Selection: Each bur is crafted using high-grade tungsten carbide powder known for its robustness and resistance to wear. The quality of the material directly impacts the tool's cutting efficiency and durability.

- Precision Grinding: Using state-of-the-art CNC grinding machines, the burs are shaped to precise specifications. This process ensures consistency in size and shape, enabling dentists to perform procedures with maximal accuracy.

- Rigorous Testing: Once manufactured, each batch of burs undergoes rigorous quality testing. This includes checking for hardness, sharpness, and durability to ensure only top-quality products reach our clients, delivering exceptional performance in dental practices.

User Hot Search:cross cut burs, double cut burr bits, CNC Grinding machine for blade, flame bur.

Related Products

Top Selling Products

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Lithuanian

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese