Factory Double Cut Burr Bits for Dental Applications

Product Details

| Cat.No. | Description | Head Length | Head Size |

|---|---|---|---|

| FG-K2R | Football | 4.5 | 023 |

| FG-F09 | Flat end taper | 8 | 016 |

| FG-M3 | Round end taper | 8 | 016 |

| FG-M31 | Taper | 8 | 018 |

Common Product Specifications

| Material | Usage | Speed | Tools |

|---|---|---|---|

| Tungsten Carbide | Dental, Industrial | 8,000-30,000rpm | Hand, Pneumatic |

Product Manufacturing Process

The manufacturing of double cut burr bits involves precision CNC grinding to ensure exact geometrical specifications and consistent quality. According to authoritative research, the process includes multiple stages of quality control checks to meet international standards. The use of high-grade tungsten carbide ensures toughness and resistance to heat and wear, making them suitable for diverse industrial applications. The process culminates with rigorous testing for durability and performance, securing the bits' status as industry-leading tools.

Product Application Scenarios

Double cut burr bits are extensively utilized in dental practices for procedures requiring precision and minimal material removal, such as cavity preparation and crown adjustments. In industrial settings, these bits excel in metalworking tasks, including deburring, shaping, and smoothing. According to industry reports, their efficiency in handling various materials like steel and titanium makes them indispensable in sectors such as automotive and aerospace, where high precision and reliability are required.

Product After-Sales Service

We offer comprehensive after-sales service, providing technical support and prompt responses to any quality concerns within 24 hours. Replacement products are delivered free of charge in the event of quality issues, ensuring customer satisfaction and trust in our factory's commitment to excellence.

Product Transportation

Partnering with reputable logistic providers DHL, TNT, and FedEx, we ensure that our products are delivered within 3-7 working days, catering to global demand with efficiency and reliability.

Product Advantages

- Factory-grade precision and reliability

- Versatile for dental and industrial applications

- Durable tungsten carbide material

- Efficient material removal

- Customizable to meet specific needs

FAQ

- What materials can double cut burr bits work on?

Our factory-produced double cut burr bits efficiently handle steel, hardened steel, copper, cast iron, and titanium, making them versatile tools for various dental and industrial applications. - How do I maintain double cut burr bits?

Regular cleaning after each use is essential. Remove any debris to maintain efficiency and prolong the lifespan of the bits. Operate at the recommended speeds to avoid overheating and potential damage. - What speed is ideal for using these burr bits?

Our factory-grade double cut burr bits perform optimally at speeds between 8,000 to 30,000 rpm, ensuring efficient material removal and precision in application. - Can these bits be used on non-metal materials?

Yes, factory double cut burr bits are also effective on non-metal materials like hard plastics and ceramics, providing versatility across different needs. - How do you ensure product quality?

Our factory utilizes state-of-the-art CNC precision grinding technology and conducts quality control checks throughout the manufacturing process to ensure reliable performance. - Are customizations available?

Yes, our factory offers customization options to meet specific requirements, providing bespoke solutions for unique application needs. - What distinguishes double cut from single cut burr bits?

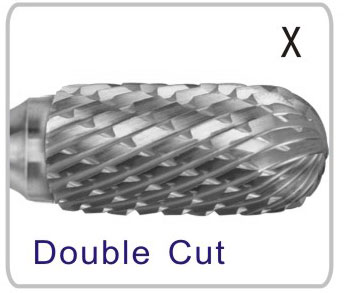

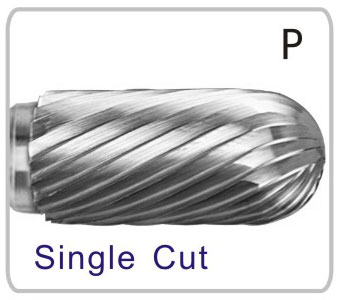

Double cut burr bits, produced in our factory, have intersecting cutting edges that create smaller chips and allow for smoother operation compared to single cut burr bits. - Is technical support available for these products?

Yes, our factory offers dedicated technical support to assist with any queries or issues, ensuring optimal performance and customer satisfaction. - How does your after-sales service work?

We provide email support within 24 hours and, if necessary, deliver replacement products for free to address any quality concerns, underlining our factory's customer-first approach. - What is the delivery time once an order is placed?

Factory-produced double cut burr bits are shipped within 3-7 working days through partnerships with DHL, TNT, and FedEx, ensuring prompt delivery worldwide.

Product Hot Topics

- How do double cut burr bits enhance dental procedures?

Our factory's double cut burr bits offer enhanced precision in dental procedures by providing controlled material removal, allowing dental professionals to perform tasks with higher accuracy and efficiency. Made from durable tungsten carbide, these bits minimize the risk of chipping, ensuring safe and reliable use in sensitive dental applications. - Why are factory double cut burr bits favored in metalworking?

The engineering precision and durability of our factory-produced double cut burr bits make them a preferred choice in metalworking. They handle tough materials such as stainless steel and cast iron with ease, providing smooth finishes and improving overall work efficiency. The unique double cut design prevents clogging, ensuring uninterrupted operation and superior results. - What makes factory double cut burr bits an asset in the aerospace industry?

In the aerospace sector, our factory's double cut burr bits are valued for their robustness and precision. They meet the stringent demands of aerospace applications by allowing precise fabrication and maintenance of components. Their reliable performance under high-stress conditions ensures that quality and safety standards are consistently met. - How do these bits contribute to automotive manufacturing?

Automotive manufacturers rely on our factory-grade double cut burr bits for tasks requiring high precision and durability. These bits efficiently manage the fabrication and repair of automotive components, offering a balance of speed and accuracy necessary for maintaining high production standards. - Are there educational resources for using double cut burr bits?

Yes, our factory provides comprehensive guides and resources for users looking to maximize the potential of double cut burr bits. These materials include best practices for different applications, ensuring users operate the bits safely and efficiently for optimal results. - Can factory double cut burr bits be used in creative industries?

Certainly, our factory's double cut burr bits are finding increasing application in creative fields such as jewelry making and sculpture, where they enable artists to achieve intricate designs and smooth finishes on various materials. - What are the cost benefits of using factory double cut burr bits?

By choosing our factory's double cut burr bits, users benefit from extended tool life and increased efficiency, translating to reduced downtime and lower long-term costs despite the initial investment in high-quality tools. - How do user experiences reflect on the quality of these bits?

User feedback consistently highlights the superior cutting performance and durability of our factory double cut burr bits, with many professionals praising their ability to handle challenging tasks without compromise, reflecting the quality assurance embedded in our manufacturing processes. - What innovations are being pursued in burr bit technology?

Our factory is at the forefront of innovation in burr bit technology, focusing on enhancing material compositions and designing cutting edge geometries to meet evolving industrial needs. This commitment to R&D ensures our products remain at the cutting edge of performance and reliability. - Why is tungsten carbide chosen for these bits?

Tungsten carbide, favored for our factory double cut burr bits, is selected due to its exceptional hardness and thermal resistance, essential for sustained performance across a range of demanding environments. This material choice underscores our commitment to providing durable and reliable tools.

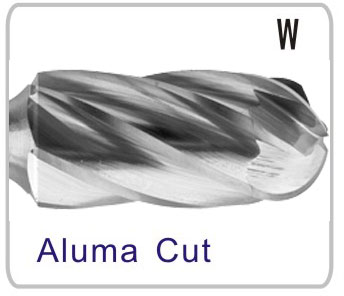

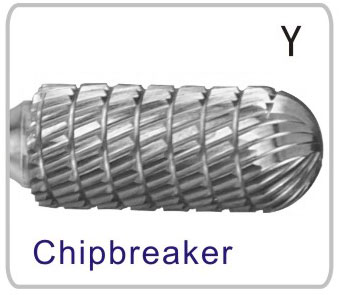

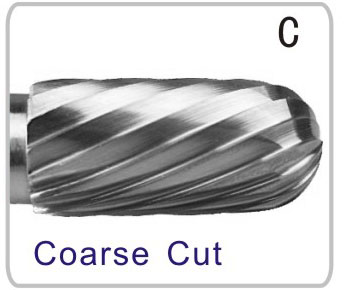

Image Description