Factory High-Quality Dental Surgical Burs

Product Main Parameters

| Cat.No. | Description | Head Length | Head Size |

|---|---|---|---|

| FG-K2R | Football | 4.5 | 023 |

| FG-F09 | Flat end tape | 8 | 016 |

| FG-M3 | Round end taper | 8 | 016 |

| FG-M31 | Round end taper | 8 | 018 |

Common Product Specifications

| Material | Application | Speed |

|---|---|---|

| Tungsten Carbide | Dental cutting, shaping | 8,000-30,000rpm |

| Diamond | Enamel and ceramics cutting | Variable |

| Steel | Polishing and finishing | Variable |

Product Manufacturing Process

Our factory employs cutting-edge 5-axis CNC precision grinding technology in the production of our dental surgical burs. This advanced method allows for unparalleled accuracy and consistency in each bur manufactured. The process involves a series of detailed steps starting from raw material selection, typically high-density tungsten carbide, which is then machined with precision to achieve the desired shape and size. Rigorous quality checks are conducted at every stage to ensure each product meets international standards for performance and safety. The combination of precision grinding and strict quality controls ensures that our dental surgical burs lead the industry in both reliability and functionality.

Product Application Scenarios

Dental surgical burs from our factory are integral to a wide array of dental procedures. In restorative dentistry, they are pivotal in cavity preparation and crown shaping, ensuring precision and efficiency. During orthodontic adjustments, these burs facilitate the fine-tuning of brackets and wires. In endodontics, they aid in accessing the pulp chamber, enhancing the efficacy of root canal treatments. Additionally, our burs are instrumental in minor surgical interventions, offering precise bone shaping and tooth removal capabilities. Their versatility and robust performance make them a top choice in modern dental practices looking to deliver premium care.

Product After-Sales Service

We are committed to excellence in after-sales service. Should any quality issues arise, our factory provides technical support and email responses within 24 hours. Defective products will be replaced free of charge. Custom packaging options are available to meet specific customer needs.

Product Transportation

Our logistics partners include DHL, TNT, and FEDEX, ensuring swift delivery within 3-7 working days. We guarantee that all products are securely packed to prevent damage during transit.

Product Advantages

- Long-lasting tungsten carbide burs

- Precision-engineered for maximum performance

- Available in a wide variety of shapes and sizes

Product FAQ

- Q1: What materials are used in your dental surgical burs? Our factory utilizes tungsten carbide and diamond for enhanced durability and performance.

- Q2: Are the burs suitable for all dental procedures? Yes, our burs are designed for a variety of dental applications including restorative, endodontic, and orthodontic procedures.

- Q3: How do I choose the right bur for my needs? Selection depends on the specific dental procedure, desired outcome, and the material being worked on.

- Q4: How should the burs be stored? Store in a dry, clean environment away from direct sunlight to maintain their integrity.

- Q5: Can your burs be sterilized? Yes, they are designed to withstand standard sterilization procedures to ensure hygiene.

- Q6: Do you offer customizations? Yes, our factory can customize burs to meet specific requirements and specifications.

- Q7: Are the burs single-use or reusable? We offer both single-use and reusable options to suit varying needs.

- Q8: What is the delivery time frame? Delivery usually takes 3-7 working days depending on the location.

- Q9: How do you handle returns and defects? We offer replacements for any defective products reported within the warranty period.

- Q10: What are the advantages of using CNC technology? CNC technology provides high precision and consistency, reducing the likelihood of human error in manufacturing.

Product Hot Topics

- Topic 1: The Evolution of Dental Surgical Burs

Our factory’s expertise in 5-axis CNC technology marks a significant advancement in the manufacturing of dental surgical burs. With a focus on precision and durability, we have revolutionized the way dental professionals approach surgery and restorative procedures.

- Topic 2: Environmental Impact of Manufacturing Dental Burs

Our factory is committed to sustainable manufacturing practices, ensuring that our dental surgical burs are produced with minimal environmental impact. This involves optimizing material use and reducing waste during the production process.

- Topic 3: Comparing Tungsten Carbide and Diamond Burs

Tungsten carbide burs offer remarkable durability, ideal for reducing tooth structure, while diamond burs excel in cutting through hard materials like enamel. Our factory provides high-quality options in both materials for comprehensive dental care.

- Topic 4: Innovations in Dental Burs Since 2017

Since proposing the “medical disposable traceable needle” in 2017, our factory has continually pushed boundaries in dental tool innovation, raising the standards for what dental burs can achieve in terms of precision and hygiene.

- Topic 5: Ensuring Patient Comfort with Advanced Dental Burs

Our factory's dental surgical burs are engineered to minimize patient discomfort through efficient and precise cutting, showcasing our commitment to enhancing patient experience during dental procedures.

- Topic 6: Role of Dental Burs in Modern Restorative Dentistry

Our burs play a crucial role in modern restorative dentistry, offering the precision needed for effective cavity preparation and crown fitting, thereby improving outcomes for patients in need of restorative work.

- Topic 7: Customizable Solutions for Dental Practices

With customizable options available, our factory provides dental practices with burs tailored to their specific procedural needs, enhancing the efficiency and effectiveness of their services.

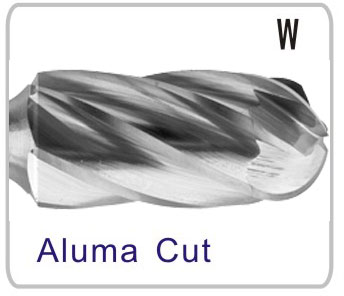

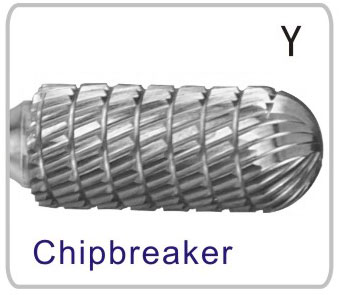

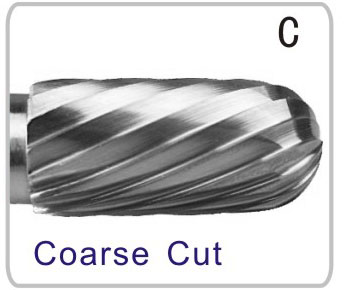

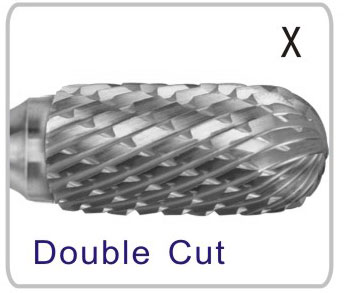

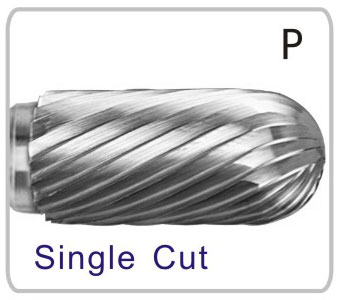

- Topic 8: Understanding the Different Types of Dental Burs

Our factory offers a comprehensive range of dental burs, each designed for specific applications such as cutting, shaping, or polishing, meeting the diverse requirements of dental practitioners.

- Topic 9: Safety Standards in Dental Bur Manufacturing

Safety in manufacturing is a cornerstone of our operations, ensuring that all dental surgical burs are produced to the highest safety standards, mitigating risks during use.

- Topic 10: The Future of Dental Surgical Burs at Our Factory

Continuous innovation and adherence to cutting-edge manufacturing techniques are at the heart of our factory’s future plans, positioning us at the forefront of dental surgical burs production globally.

Image Description