Factory-Made Cone Burr Bit for Precision Cutting

Product Main Parameters

| Parameter | Details |

|---|---|

| Material | Tungsten Carbide |

| Speed Range | 8,000-30,000 RPM |

| Shape | Cone |

| Applications | Wood, Metal, Plastics |

Common Product Specifications

| Specification | Details |

|---|---|

| Diameter | 6mm |

| Shank Size | 3mm |

| Weight | 0.1kg |

Product Manufacturing Process

The cone burr bit is manufactured using advanced CNC grinding technology to achieve high precision. The process involves the selection of high-strength tungsten carbide materials, followed by shaping and cutting using 5-axis CNC machines. This ensures that each product meets stringent quality control standards, offering durability and exceptional performance. The use of tungsten carbide allows the bits to withstand high rotational speeds without rapid wear, making them suitable for various industrial applications. According to recent studies, the precision of CNC technology in manufacturing these burr bits significantly enhances their performance, giving them an edge in the market.

Product Application Scenarios

Cone burr bits are utilized across diverse industries due to their adaptability and precision. In woodworking, they achieve intricate carvings and smooth finishes, ideal for craftsmen and hobbyists alike. Metalworking benefits from their ability to deburr, smooth welds, and enlarge holes with precision, particularly critical in aerospace and automotive sectors. The dental field also uses these bits for prosthetic shaping. Studies highlight the importance of tool precision and material efficiency in reducing time and improving product quality, making cone burr bits a preferred choice for professionals seeking reliability from a factory setting.

Product After-Sales Service

Our factory provides comprehensive after-sales support, including technical assistance and product replacement for defects. We ensure quick responses to customer inquiries and guarantee satisfaction with our cone burr bits.

Product Transportation

We partner with DHL, TNT, and FEDEX to deliver products worldwide, ensuring rapid shipping within 3-7 working days from our factory.

Product Advantages

Our factory ensures precision and reliability, offering customizable solutions for various needs. Cone burr bits undergo rigorous quality checks to maintain high standards.

Product FAQ

- 1. What materials are cone burr bits made from?

Our factory uses high-strength tungsten carbide, known for its durability and ability to withstand high-speed operations without significant wear. - 2. How do I ensure proper use of cone burr bits?

Maintain the recommended speed and apply appropriate pressure. Use lubrication for metal materials to extend tool life. - 3. Can these bits be used on plastics?

Yes, but ensure slow speeds to prevent melting at contact points. - 4. Are these bits suitable for dental applications?

Indeed, they are optimized for precision tasks such as dental prosthetic shaping. - 5. Is the cone shape effective for woodworking?

Yes, it allows detailed work like engraving and chamfering in tight areas. - 6. Do you provide custom solutions?

Our factory can customize tungsten carbide burrs to meet specific customer needs. - 7. How do I maintain cone burr bits?

Regular cleaning and proper storage in a dry environment are essential for longevity. - 8. What if there's a quality issue?

Contact us within 24 hours, and we will provide replacement products for free. - 9. Can these be used in jewelry making?

Yes, they are excellent for engraving designs on metals and stones. - 10. Is factory direct buying available?

Yes, purchasing directly from our factory ensures quality and cost-effectiveness.

Product Hot Topics

- 1. Precision and Versatility in Cone Burr Bits

Our factory-developed cone burr bits are renowned for their precision and adaptability across numerous industries. Professionals from woodworking to metal fabrication appreciate the flexibility offered by these tools. With options for customization and a commitment to quality, our factory ensures that each burr bit meets specific project requirements. This reliability is backed by advanced manufacturing processes that prioritize accuracy and durability. - 2. Enhancing Tool Longevity

Maintaining the integrity of cone burr bits is crucial for prolonged usage. Users often inquire about the best practices for preservation. Our factory suggests regular cleaning to remove debris and ensure optimal performance. Storing these tools in a dry, organized manner prevents rust and potential damage. By following these maintenance tips, users can expect consistent quality and performance from their cone burr bits.

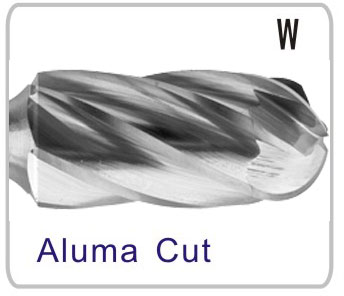

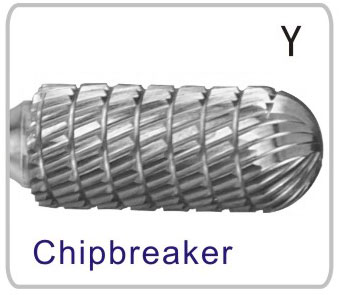

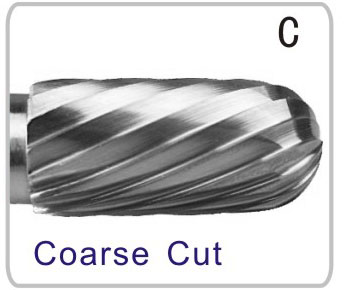

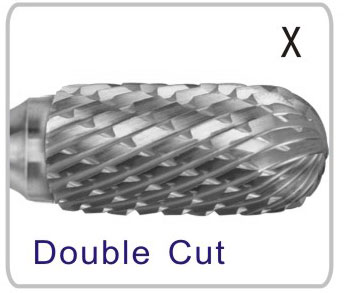

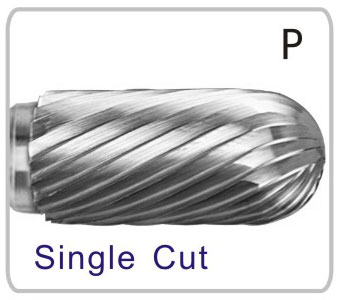

Image Description