Factory-made Diamond Tapered Bur for Precise Dental Use

Product Main Parameters

| Parameter | Specification |

|---|---|

| Material | Stainless Steel/Tungsten Carbide |

| Coating | Diamond Particles |

| Tapered Design | Yes |

| Head Size | 023, 018 |

| Head Length | 4.4, 1.9 |

Common Product Specifications

| Specification | Details |

|---|---|

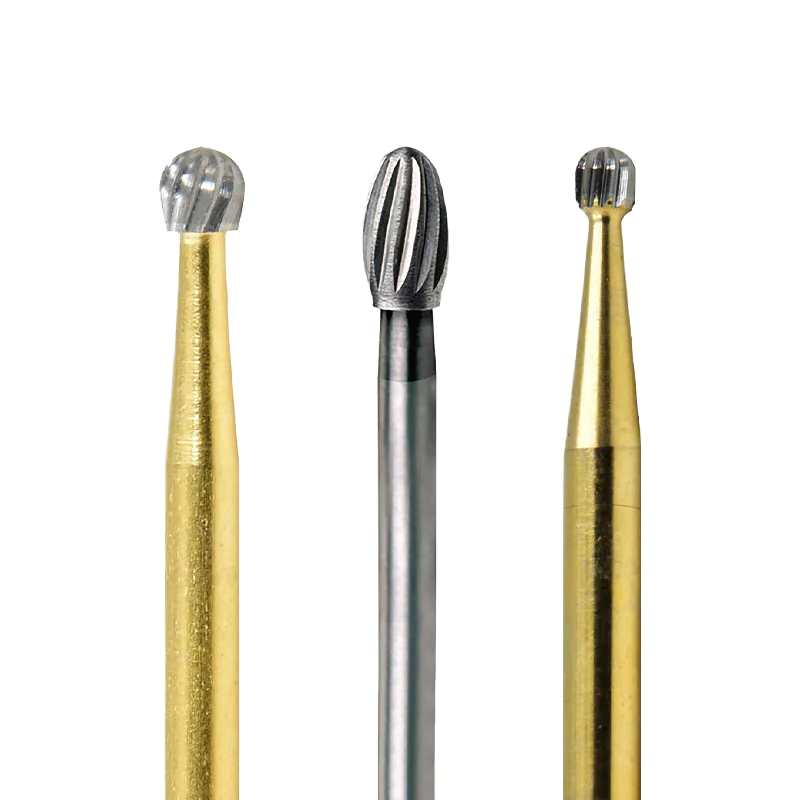

| Flutes | 12 Flutes FG7006, RA7006 |

| Blade Type | Straight and Spiraled |

| Shank Material | Surgical Grade Stainless Steel |

| Sterilizable | Up to 340°F/170°C (Dry heat) or 250°F/121°C (Autoclave) |

Product Manufacturing Process

The diamond tapered burs are manufactured using high-grade stainless steel and tungsten carbide, providing a robust shank and cutting surface. The diamond coating is applied via an electroplating process, ensuring maximum adherence and durability. This process involves the precise deposition of diamond particles to a homogenous surface, followed by stringent quality control protocols to ensure each bur meets international standards.

Product Application Scenarios

Diamond tapered burs are integral to various dental procedures, including restorative and orthodontic applications. In restorative dentistry, they facilitate the efficient removal of decayed enamel and dentin while maintaining the structural integrity of the tooth. In orthodontics, these burs aid in the precise removal of adhesives post-bracket removal, ensuring minimal enamel damage and optimal oral health outcomes.

Product After-sales Service

Our factory provides comprehensive after-sales support, including product replacement for manufacturing defects, technical guidance for optimal bur usage, and customer service support for any inquiries. We ensure that our clients are satisfied with their purchase and offer extended service plans as an option.

Product Transportation

Products are securely packaged and shipped via trusted courier services to ensure safe delivery. We offer international shipping options with tracking services to keep you updated on the delivery status of your order from our factory.

Product Advantages

- Precision and Control: Ensures accurate shaping and cutting.

- Durability: Long-lasting diamond coating reduces replacement frequency.

- Versatility: Suitable for a range of dental procedures.

Product FAQ

- What are diamond tapered burs used for? Diamond tapered burs are primarily used for cutting and shaping tooth structures during dental procedures, such as cavity preparations, crown work, and veneer placement, owing to their precision and control.

- How are these burs sterilized? The burs can be sterilized using dry heat up to 340°F/170°C or by autoclaving at 250°F/121°C, ensuring they remain safe and effective for repeated use.

- What makes these burs durable? The use of fine-grain tungsten carbide for the blades and surgical-grade stainless steel for the shank, combined with a diamond coating, makes them highly durable and resistant to wear.

- Why choose our factory's diamond tapered burs? Our factory ensures quality through stringent manufacturing processes, offering high precision burs that are cost-effective due to their durability and performance efficiency.

- Are custom sizes available? Yes, our factory can produce diamond tapered burs in custom sizes according to your specific requirements and preferences.

- How is heat generation managed when using these burs? Adequate cooling techniques, such as water sprays, are used during procedures to mitigate heat generation and protect tooth structure.

- What is the difference between straight and spiraled blades? Straight blades offer excellent control with no spiraling, ideal for composites. Spiraled blades are standard for metals and amalgam finishing, offering a superior finish.

- Can these burs be used in all dental handpieces? Yes, they are designed to fit most standard dental handpieces, providing versatility in their usage.

- What is the lifespan of a diamond tapered bur? The lifespan varies based on usage, but the high-quality materials and construction extend the lifespan compared to standard burs.

- How does our factory ensure quality? Our factory employs advanced manufacturing technologies and rigorous quality checks to ensure consistent product quality that meets global standards.

Product Hot Topics

- Unmatched Precision in Dental Procedures Our factory's diamond tapered burs provide unmatched precision in dental procedures, making them indispensable tools for restorative and orthodontic applications. The high-quality materials combined with fine diamond grit ensure smooth, precise cuts necessary for the delicate nature of dental work. Dentists worldwide rely on these burs for their durability and accuracy, making them a staple in modern dental practices. With advancements in technology, these burs continue to evolve, offering even greater benefits to both dental professionals and patients.

- Optimizing Adhesive Removal in Orthodontics Our factory's diamond tapered burs have revolutionized adhesive removal in orthodontics. Specially designed to minimize enamel damage, these burs provide controlled debonding that ensures a smooth finish without scratching the enamel. The precision of the burs reduces the risk of enamel loss, a common concern post-bracket removal, and enhances patient satisfaction by maintaining oral health. Their efficiency in adhesive removal makes them a preferred choice among orthodontists looking for reliable and effective tools.

Image Description

There is no picture description for this product