wholesale fg 330 bur - manufacturer, supplier, factory

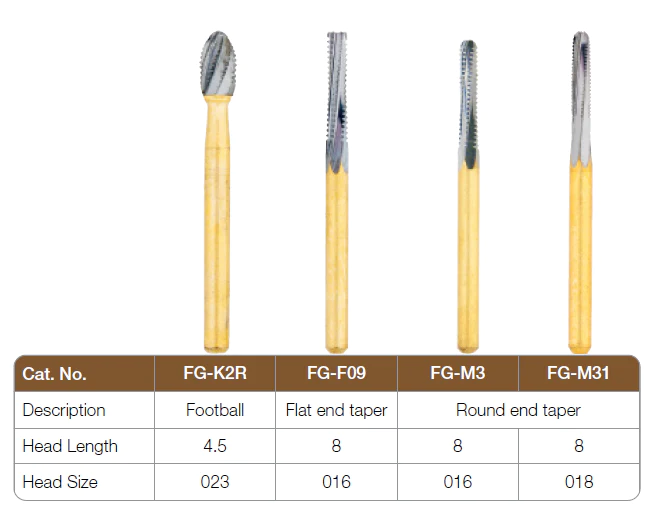

The FG 330 bur is a precision instrument used in dental procedures, designed for cutting and shaping tooth structure. Known for its high-speed performance, the FG (Friction Grip) bur is essential for efficient tooth preparation, ensuring smooth and precise results in restorative dentistry.

At our wholesale manufacturing facility, we adhere to stringent quality control and testing standards to ensure our FG 330 burs meet the highest industry expectations. Four key standards guide our process:

- ISO Certification: Compliance with international ISO standards guarantees that our burs meet global quality and safety benchmarks.

- Material Consistency: Rigorous testing for material integrity and consistency ensures that each bur delivers optimal performance and durability.

- Performance Testing: Each batch undergoes thorough testing for sharpness, balance, and durability to ensure consistent high-speed cutting performance.

- Visual Inspections: Detailed visual inspections are conducted to detect any surface imperfections or defects, ensuring only flawless products reach our customers.

Our production process is designed to maintain the highest standards of precision and efficiency:

- Precision Engineering: Utilizing state-of-the-art CNC machinery, our FG 330 burs are crafted to exact specifications, ensuring precision in every cut.

- Quality Finishing: Each bur undergoes a meticulous finishing process to enhance sharpness and smoothness, providing a superior cutting experience for dental professionals.

User Hot Search:701 dental bur, inverted cone burr, lindemann side cutting bur, 6 axis machining.

Related Products

Top Selling Products

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Lithuanian

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese