High Quality Dental Bur - Tungsten Carbide Surgical Burs

| Cat.No. | Head Size | Head Length | Total Length |

|---|---|---|---|

| Zekrya23 | 016 | 11 | 23 |

| Zekrya28 | 016 | 11 | 28 |

Product Manufacturing Process

The production of our high-quality dental carbide burs involves a meticulous process to ensure durability and precision. Initially, high-grade tungsten carbide powder is sintered to form a solid, robust piece - achieving the perfect balance between hardness and toughness. CNC machine lines, each with dedicated customer databases, execute the shaping of the burs with unrivaled accuracy. The cutting edge stability is further enhanced through a series of precise grinding and sharpening procedures, supervised by experts in the field. The final product undergoes stringent quality control checks, including tests for welding fastness, to ensure it meets industry standards. Our commitment to quality is underscored by the use of advanced manufacturing technologies and rigorous testing protocols.

Product Seeking Cooperation

We at Boyue are actively seeking partnerships with distributors, dental clinics, and industrial clients worldwide to expand the reach of our high-quality tungsten carbide burs. We believe that collaboration is key to delivering superior dental solutions and enhancing patient care. By partnering with us, you gain access to a reliable supply chain, customized product solutions, and continuous technical support. We are committed to fostering long-term relationships built on trust, quality, and mutual success. Join us in our mission to revolutionize dental care with precision-engineered tools. Contact us for partnership opportunities, and let us grow together in this dynamic market.

Product Application Industry

The tungsten carbide dental burs are a critical tool across various applications in the dental and medical fields. Their superior cutting and drilling capabilities make them indispensable in procedures requiring material preparation and adjustment, such as cavity preparation, crown cutting, and root canal treatments. Unlike diamond burs, which are often preferred for cutting zirconia or ceramic crowns, carbide burs ensure a smoother finish, making them ideal for tasks that demand precision and finesse. Beyond dentistry, these versatile burs also find applications in industrial settings where precision cutting and shaping are required. Our comprehensive range of carbide burs is designed to meet the diverse needs of practitioners and industries globally, ensuring optimal performance and high-quality results.

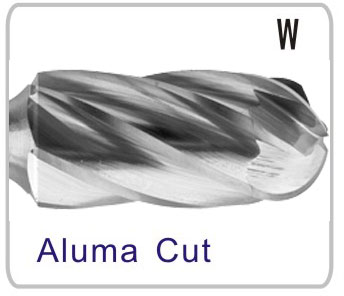

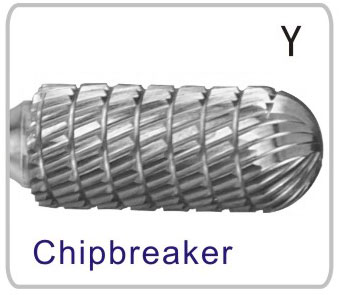

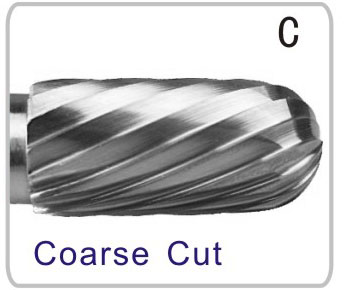

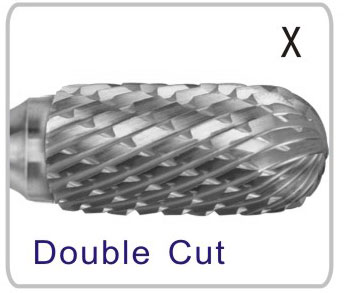

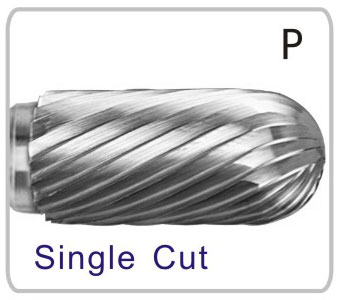

Image Description