High Quality Dental Carbide Endo Z Bur for Pulp Chamber

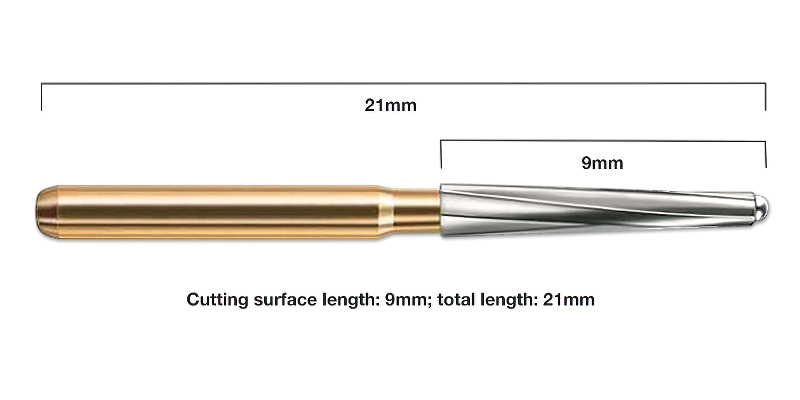

| Cat.No. | Head Size | Head Length | Total Length |

|---|---|---|---|

| EndoZ | 016 | 9 | 23 |

Product Production Process

The production process of the High Quality Dental Carbide Endo Z Bur for Pulp Chamber begins with the selection of premium carbide materials known for their strength and durability. The raw carbide is precision-engineered to form a unique combination of round and cone shapes, facilitating seamless access and preparation of the pulp chamber. Using state-of-the-art CNC machines, the burs are meticulously crafted to ensure accuracy and consistency in each piece. The cutting edges are finely honed for optimal performance, and the non-cutting tips are carefully rounded to prevent inadvertent damage to dental structures. Each bur undergoes rigorous quality control checks to meet industry standards, ensuring a high-quality product every time.

Product Manufacturing Process

The manufacturing of the Endo Z Bur involves advanced techniques to ensure the precise melding of form and function. The initial phase includes designing the bur's complex geometry through CAD software to create a digital model. This model guides the CNC machining to shape the bur with exact specifications. The sharpening process is crucial, where the lateral cutting edges are sharpened to achieve the desired level of sharpness for effective chamber preparation. The burs are then subjected to a coating process to enhance their wear resistance and longevity. Finally, the products are sterilized and packaged in a controlled environment, ready to aid dental professionals in performing intricate procedures with finesse.

Product Team Introduction

Our dedicated team behind the High Quality Dental Carbide Endo Z Bur is comprised of experienced dental professionals, engineers, and quality assurance experts. With years of industry experience, our dental professionals provide valuable insights into practical applications and user needs, guiding product development to meet real-world challenges. Our engineering team leverages cutting-edge technology and innovative design principles to ensure each bur meets stringent performance criteria. Quality assurance experts meticulously test every product batch to guarantee safety and efficiency. Together, we are committed to delivering precision tools that enhance the capabilities of dental practitioners, ensuring superior patient outcomes and advancing the field of endodontics.

Image Description

There is no picture description for this product