wholesale inverted cone burr - manufacturer, supplier, factory

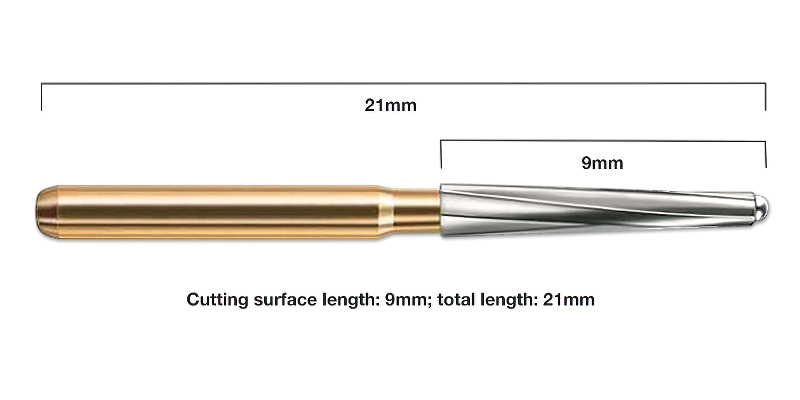

An inverted cone burr is a rotary tool used extensively in industries for precision cutting, shaping, and grinding materials such as metal, wood, or plastic. Its unique inverted cone shape allows for versatile applications, especially in creating grooves, slots, and intricate designs. Popular in manufacturing and construction, these tools enhance efficiency and workmanship.

Product Maintenance and Care Recommendations:

- Regularly clean your inverted cone burrs after each use to prevent material build-up that can affect performance. Use a wire brush or compressed air to remove debris.

- Ensure to store burrs in a dry environment to avoid rusting, especially those made from high-speed steel. Consider using protective cases for prolonged tool life.

Advantages Compared with Peers:

- Superior Material Quality: Our inverted cone burrs are crafted from premium-grade materials, offering enhanced durability and wear resistance that outlasts competitor products.

- Precision Engineering: Each burr is manufactured with meticulous attention to detail, providing smoother performance and reduced vibration, making them ideal for demanding applications.

- Cost-Effective Solutions: As a wholesale factory, we offer competitive pricing without compromising on quality, allowing businesses to maximize their investment in top-tier tools.

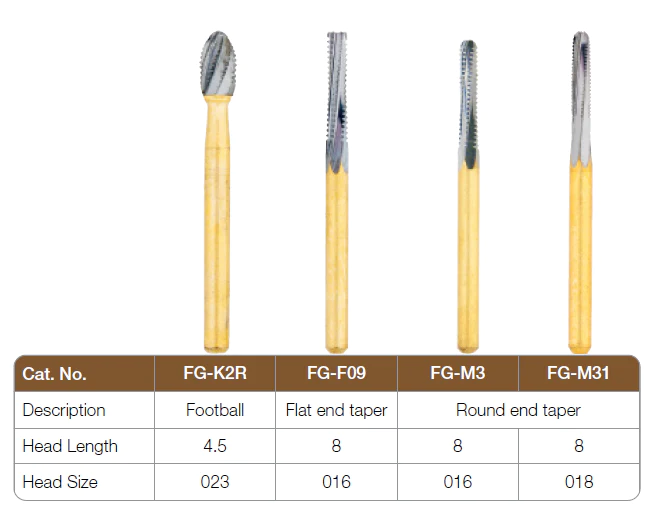

User Hot Search:carbide and diamond burs, 703 surgical bur, 245 bur, 6 axis cnc milling machine.

Related Products

Top Selling Products

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Lithuanian

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese