Manufacturer Inverted Bur Dental Precision Tool

Product Main Parameters

| Cat.No. | Description | Head Length | Head Size |

|---|---|---|---|

| FG-K2R | Football | 4.5 | 023 |

| FG-F09 | Flat end tape | 8 | 016 |

| FG-M3 | Round end taper | 8 | 016 |

| FG-M31 | Round end taper | 8 | 018 |

Common Product Specifications

| Material | Type |

|---|---|

| Tungsten Carbide | Single-piece |

Product Manufacturing Process

Boyue, renowned as a leading manufacturer, utilizes advanced 5-axis CNC precision grinding technology to produce high-quality inverted bur dental tools. Drawing from authoritative research in material sciences and tool manufacturing, Boyue employs a comprehensive process including material selection, CNC machining, quality inspection, and surface finishing. The use of single-piece tungsten carbide ensures durability and precision, while the CNC database for each customer guarantees consistent quality. Through rigorous testing for weld fastness and cutting efficiency, Boyue consistently delivers reliable tools capable of high-speed operations (8,000-30,000rpm), minimizing chip loading and maximizing tool life.

Product Application Scenarios

Inverted bur dental tools are essential in restorative dentistry, particularly for cavity preparation and the creation of retentive features. According to research, their unique inverted cone design is optimal for producing undercuts that secure fillings. These tools are pivotal in minimally invasive carious dentine removal, promoting tooth integrity. Further, their precision in shaping and smoothing cavity walls enhances the retention and durability of restorations. Boyue's inverted burs are valuable in shaping, de-burring, and finishing various materials, synonymous with precision, efficiency, and versatility.

Product After-Sales Service

- Technical support and email response within 24 hours for quality issues.

- Free replacement delivery for confirmed quality issues.

- Flexible packaging requirements to meet customer needs.

Product Transportation

- Long-term partnerships with DHL, TNT, and FEDEX ensure delivery within 3-7 working days.

Product Advantages

- Precision: Exceptional design for precise cavity preparations.

- Efficiency: High-speed and sharp cutting capabilities.

- Customization: Customized burrs available for specific needs.

Product FAQ

- What is the primary use of an inverted bur dental tool? Inverted bur dental tools are primarily used for preparing cavities, creating undercuts, and ensuring mechanical retention of fillings, playing a critical role in restorative dentistry procedures.

- How does the manufacturer ensure product quality? The manufacturer employs all CNC machine lines, individual CNC databases for clients, and rigorous testing for weld fastness and material durability, ensuring consistent product quality and performance.

- Can inverted bur dental tools be customized? Yes, the manufacturer provides customization options for special tungsten carbide burrs based on customer requirements, allowing for tailored solutions to meet specific procedural needs.

- What materials are inverted burs made of? Inverted burs are made from durable materials like single-piece tungsten carbide, ensuring high accuracy, longevity, and excellent cutting experiences.

- Are these tools suitable for different materials? Yes, inverted bur dental tools are versatile and can be used on a variety of materials including metals, ceramics, plastics, and more, adjusting speeds according to material hardness.

- What is the delivery timeline for orders? Dental burs are delivered within 3-7 working days through reliable shipping partners such as DHL, TNT, and FEDEX.

- How are returned products handled? In case of quality issues, defective products are replaced free of charge, with a commitment to resolving concerns promptly to ensure customer satisfaction.

- What is the operational speed range for these tools? The operational rotary speed for inverted bur dental tools ranges from 8,000 to 30,000 rpm, allowing for adaptable use depending on material and procedural requirements.

- Do you provide technical support? Yes, technical support is available with a promise of email replies within 24 hours to address any quality or operational inquiries from customers.

- What benefits do the tungsten carbide burs offer? Tungsten carbide burs provide a longer operational life, high cutting edge stability, and are ideal for shaping, smoothing, and material removal across various industrial applications.

Product Hot Topics

- The Importance of Material Choice in Inverted Bur Dental Tools: Quality and durability in inverted bur dental tools are heavily influenced by the choice of materials. As a leading manufacturer, Boyue's use of single-piece tungsten carbide ensures excellent performance and precision in dental procedures. This material not only supports high-speed operations but also enhances the longevity and reliability of the tools, crucial for achieving optimal patient outcomes.

- Understanding the Unique Design of Inverted Bur Dental Tools: The inverted bur dental tool is distinguished by its inverted cone shape, which is pivotal in creating retentive features within cavities. This design is an innovation that improves the mechanical retention of fillings, directly impacting the success rate of restorative procedures. The precise engineering of these burs by reputable manufacturers like Boyue results in reliable, efficient tools essential for modern dentistry.

- Exploring the Versatility of Inverted Bur Dental Tools: Inverted bur dental tools are not only vital in cavity preparation but also versatile across various applications. From creating undercuts to smoothing cavity walls, these tools adapt effectively to different tasks. Their efficiency in material removal and precision shapings, backed by Boyue's manufacturing excellence, make them indispensable in both dental operations and broader material processing industries.

- How to Maintain Inverted Bur Dental Tools for Longevity: Proper maintenance of inverted bur dental tools is vital for sustained performance and longevity. This includes regular cleaning, sterilization, and correct handling protocols. Boyue emphasizes the importance of maintenance, offering guidance to ensure tools remain sharp and effective, thereby enhancing procedural success and tool lifespan significantly.

- The Role of CNC Technology in Manufacturing Inverted Bur Dental Tools: CNC technology plays a fundamental role in the precision manufacturing of inverted bur dental tools. Through advanced 5-axis CNC machining, manufacturers like Boyue achieve unparalleled accuracy and quality consistency. This technology allows for the customization of burrs to meet specific procedural needs, demonstrating an intersection of cutting-edge tech and skilled craftsmanship in tool production.

- Adapting to Material Types with Inverted Bur Dental Tools: The adaptability of inverted bur dental tools to various materials is a testament to their engineering excellence. While they perform optimally on hard materials like alloys and ceramics, they are equally effective on softer materials, provided the appropriate speeds and techniques are employed. This versatility makes them a vital component in diverse industrial and clinical applications.

- The Future of Dental Tools with Inverted Bur Technology: Inverted bur dental technology is poised for continued innovation, with manufacturers like Boyue leading the charge in integrating advanced materials and design improvements. Future developments are expected to further enhance their precision, efficiency, and adaptability, reinforcing their crucial role in evolving dental and material processing practices.

- Maximizing Efficiency with Inverted Bur Dental Tools: Efficiency is a hallmark of inverted bur dental tools, thanks to their ability to perform high-speed, precise cuts. Boyue's commitment to utilizing top-tier materials and manufacturing processes ensures that these tools are not only efficient but also reliable across various operational contexts, whether in dentistry or industrial material handling.

- The Significance of Quality Assurance in Manufacturing: Quality assurance is central to the manufacturing process of inverted bur dental tools. Boyue's rigorous testing protocols, including welding fastness and cutting efficiency tests, confirm that each tool meets high-performance standards. This commitment to quality empowers dental professionals with reliable, effective tools that elevate the standard of care.

- Customer Satisfaction and After-Sales Service Excellence: Customer satisfaction is pivotal, with comprehensive after-sales services ensuring issues are rectified swiftly. From 24-hour support response to free replacements for quality concerns, the post-purchase experience is a testament to Boyue's dedication as a customer-oriented manufacturer, reinforcing trust and dependability in their inverted bur dental tools.

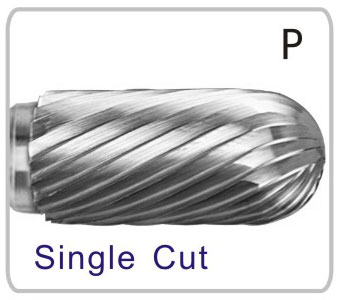

Image Description