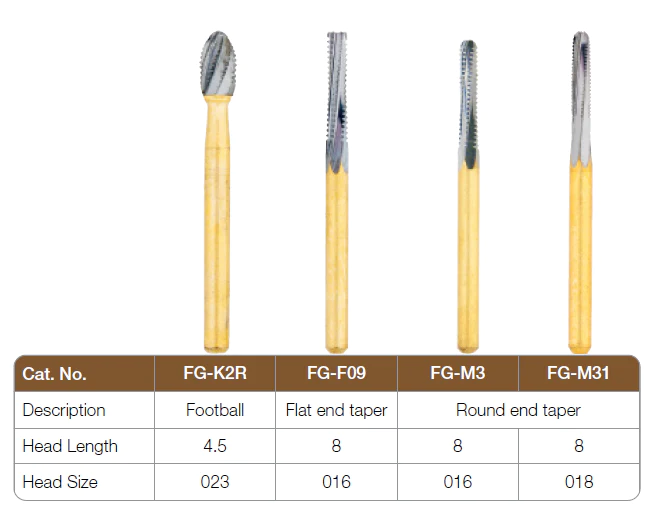

wholesale pear bur dental - manufacturer, supplier, factory

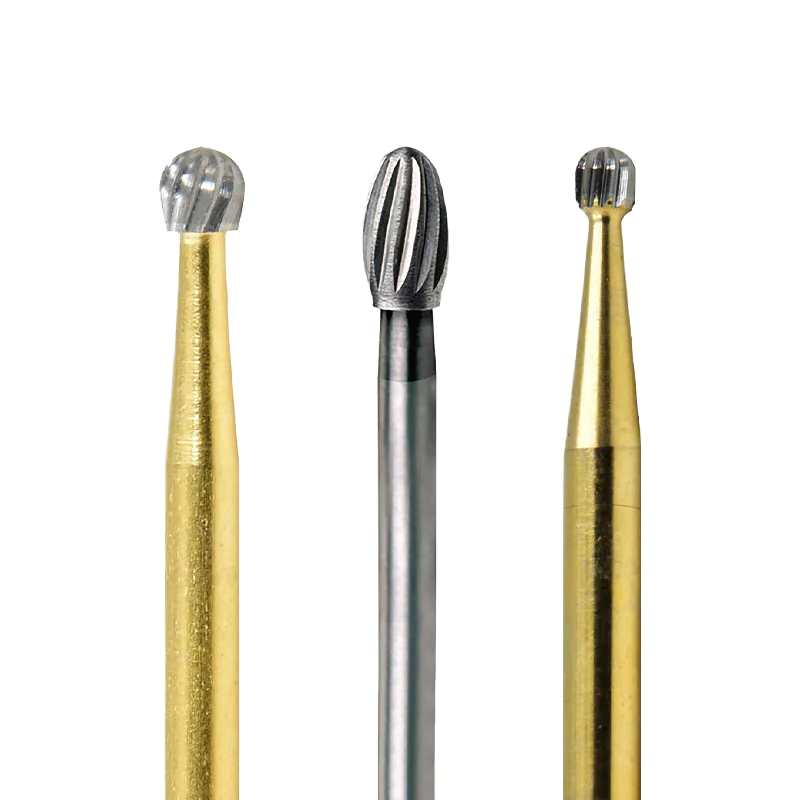

Pear bur dental tools are precision-engineered instruments used by dental professionals, particularly for cavity preparation and restoration procedures. Named for their unique pear-shaped cutting head, these tools ensure efficient and precise cutting, providing optimal control for the practitioner. Manufactured to high standards, pear burs deliver enhanced durability and performance in dental applications.

Product Maintenance and Care Recommendations:

1. Regular Cleaning: Ensure that pear burs are cleaned after every use. Use a non-corrosive disinfectant bath to remove debris and contaminants, then rinse thoroughly with distilled water.

2. Proper Storage: Store the burs in a dry, temperature-controlled environment. Utilize a dedicated bur block to prevent contact with other tools, reducing the risk of contamination and damage.

3. Inspection for Wear: Routinely check for signs of wear such as dullness or chipping. Replace any burs that show significant deterioration to maintain efficient cutting performance and patient safety.

Production Process Descriptions:

1. Precision Machining: Our pear burs are crafted through advanced CNC machining techniques, allowing for fine-tuned accuracy and consistency in each bur. This ensures each tool meets stringent industry standards for quality.

2. Quality Control: Each pear bur undergoes rigorous quality control checks. This includes testing for sharpness, balance, and durability to ensure they meet our high standards. Every batch is meticulously inspected to guarantee top-tier performance for dental professionals.

User Hot Search:busch burs, round surgical bur, burs in dentistry, interdental burs.

Related Products

Top Selling Products

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Lithuanian

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese