Solid Carbide Burr Set: High Quality Dental Metal & Crown Cutters

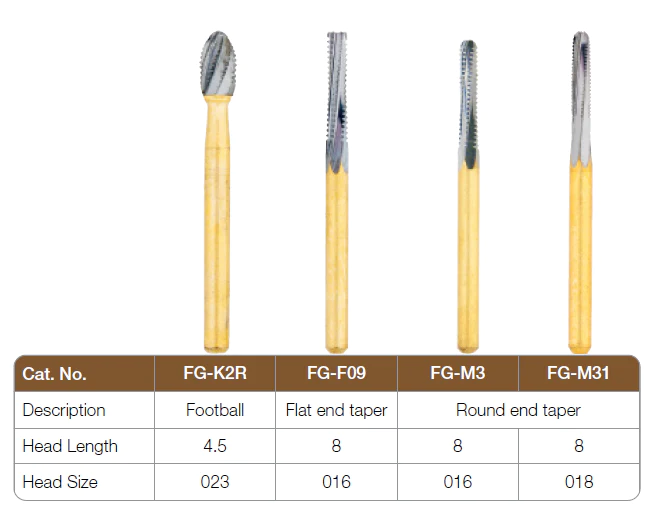

| Cat.No. | Description | Head Length | Head Size |

|---|---|---|---|

| FG-K2R | Football | 4.5 | 023 |

| FG-F09 | Flat end tape | 8 | 016 |

| FG-M3 | Round end taper | 8 | 016 |

| FG-M31 | Round end taper | 8 | 018 |

| Tooth Type | Material Recommended | Usage |

|---|---|---|

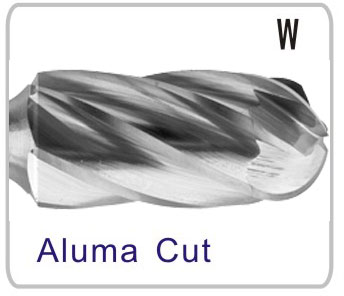

| Aluminum Cut | Nonferrous & Nonmetallic materials | Rapid stock removal |

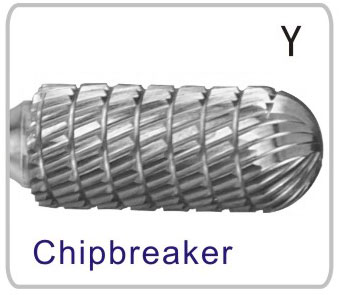

| Chip Breaker Cut | Various metals | Improved operator control |

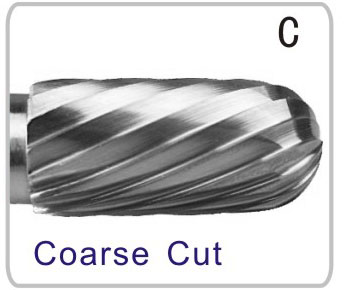

| Coarse Cut | Soft materials: Copper, Brass, Aluminum | Prevents chip loading |

| Diamond Cut | Heat treated and tough alloy steels | Small chip production |

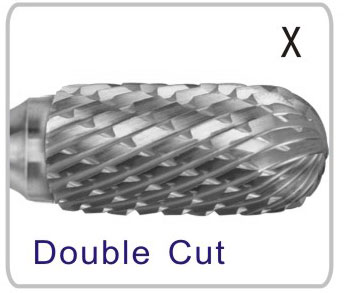

| Double Cut | All materials | Better operator control |

| Standard Cut | Ferrous materials | General purpose |

Frequently Asked Questions

1. What materials are suitable for the Solid Carbide Burr Set?

The Solid Carbide Burr Set is versatile and can be used on various materials including hardened steel, stainless steel, cast iron, nonferrous metals, fired ceramics, plastic, and hard wood. It performs exceptionally well on materials with hardness above HRC70.

2. How should I adjust the rotary speed for different materials?

The optimal rotary speed varies depending on the material: for hard woods, use higher speeds; for metals, slower speeds are recommended; and for plastics, very slow speeds are necessary to avoid melting at the point of contact.

3. What tools can be used to drive the tungsten carbide burrs?

Tungsten carbide burrs can be driven by hand electric tools or pneumatic tools, and can also be used on machine tools. The recommended rotary speed is between 8,000 and 30,000 rpm for optimal performance.

4. Can the burrs be customized?

Yes, Boyue offers customization options for its tungsten carbide burrs. Customers can request special shapes and sizes tailored to their specific needs, ensuring the perfect tool for every application.

5. What is the expected operational life of the burrs?

The Solid Carbide Burr Set is designed with durable tungsten carbide for a long operational life. The precise cutting edge stability and tenacity ensure that these burrs maintain their efficacy over extended periods, providing value and reliability for dental and metalworking applications.

Image Description