Top Manufacturer's Surgical 557 Bur for Precision Cuts

Product Main Parameters

| Cat.No. | Description | Head Length | Head Size |

|---|---|---|---|

| FG-K2R | Football | 4.5 | 023 |

| FG-F09 | Flat end tape | 8 | 016 |

| FG-M3 | Round end taper | 8 | 016 |

| FG-M31 | Round end taper | 8 | 018 |

Common Product Specifications

| Material | Speed | Application |

|---|---|---|

| Tungsten Carbide | 8,000-30,000rpm | Dental, Surgical |

Product Manufacturing Process

The manufacturing of surgical 557 bur involves precision grinding using 5-axis CNC technology. Tungsten carbide is selected for its hardness and durability, providing a long-lasting and sharp cutting edge. Each bur undergoes a strict quality assurance process to ensure consistency in performance. According to scholarly papers, the incorporation of advanced CNC grinding technology in manufacturing enhances the precision and reliability of dental burs, offering superior cutting efficiency and reduced heat generation, thereby improving surgical outcomes and patient safety.

Product Application Scenarios

Surgical 557 burs are vital in dental and oral surgery settings. They are used for cavity preparation, bone removal, and crown preparation. Studies highlight the importance of cylindrical and cross-cut designs in enhancing cutting efficiency and producing smoother, cleaner cuts. These features facilitate precise work in hard tissues like enamel and bone, reducing operation time and improving procedural accuracy, which is crucial for successful dental restorations and surgeries.

Product After-Sales Service

- 24-hour technical support

- Free replacement for quality issues

- Custom solutions and design support

Product Transportation

We partner with DHL, TNT, and FedEx to ensure timely delivery within 3-7 working days globally.

Product Advantages

- High precision cutting for efficient procedures

- Durable tungsten carbide construction

- Reduced heat generation for safety

Product FAQ

- What materials are surgical 557 burs made of? Our surgical 557 burs are manufactured from high-quality tungsten carbide, known for its durability and precision, essential for efficient dental procedures.

- How should surgical 557 burs be sterilized? Proper sterilization is crucial to prevent cross-contamination. They are designed to be autoclavable, and you should follow the manufacturer's guidelines for effective sterilization.

- How often should surgical 557 burs be replaced? Regular inspection is necessary as burs wear over time. Replacement is recommended when there is a noticeable decrease in cutting efficiency to maintain optimal performance.

- Can these burs be used on materials other than dental tissues? While primarily designed for dental applications, their precise cutting capabilities allow use on other hard materials as appropriate, ensuring careful selection based on material properties.

- What is the ideal speed for using surgical 557 burs? The recommended rotary speed ranges between 8,000 to 30,000 rpm. Adjust the speed according to the hardness of the material to maximize efficiency and minimize potential damage.

- Are there different designs available for surgical 557 burs? Yes, surgical 557 burs come in various designs, including different head shapes and sizes, to suit specific procedural needs and cutting preferences.

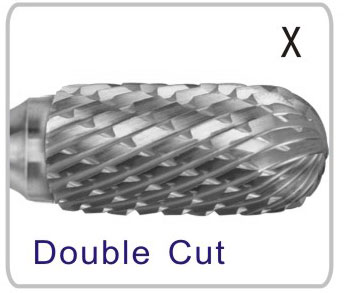

- How does the cross-cut design benefit the surgical 557 bur? The cross-cut design enhances cutting efficiency, minimizes heat generation, and creates smooth walls and floors, critical for successful dental restorations and surgeries.

- What application scenarios are ideal for surgical 557 burs? They are ideal for various dental procedures, including cavity preparation, bone contouring, and crown preparation, offering precision and efficiency in clinical settings.

- Why is heat control important in surgical 557 burs? Controlling heat is vital to prevent damage to dental tissues and pulp during cutting. The bur's design helps in maintaining lower temperatures even during aggressive material removal.

- How does Boyue ensure the quality of its surgical 557 burs? Boyue employs CNC precision grinding technology and rigorous testing for welding fastness and cutting effectiveness, ensuring consistent and reliable product quality.

Product Hot Topics

- The Importance of Precision in Surgical 557 Burs Precision in surgical 557 burs is crucial for successful dental procedures. Boyue, a reputed manufacturer, ensures top-notch quality through CNC precision grinding technology, offering dental professionals tools that enhance accuracy and efficiency in surgeries, leading to better patient outcomes.

- Innovations in Dental Burs: A Focus on Surgical 557 Boyue leads dental innovation with its surgical 557 burs, designed with advanced cross-cut technology for superior cutting. As a leading manufacturer, Boyue emphasizes durability and heat control, ensuring its products meet the high demands of dental surgeons and clinicians worldwide.

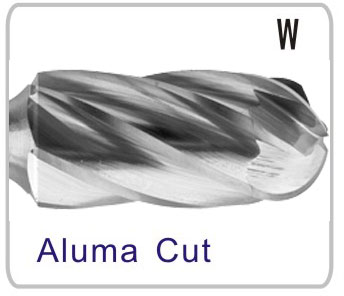

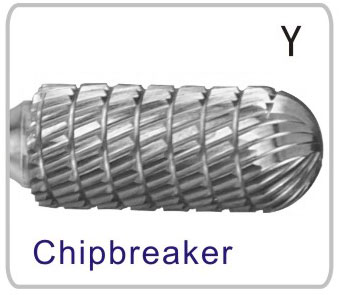

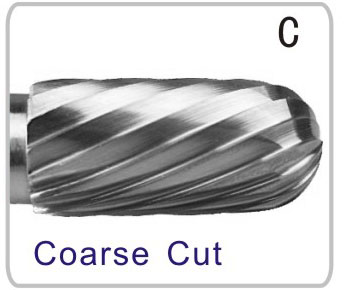

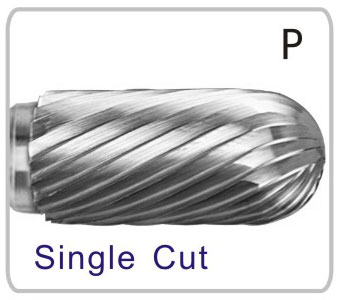

Image Description