Wholesale Dental Tungsten Carbide Burs for Precision Use

Product Main Parameters

| Cat.No. | Description | Head Length | Head Size |

|---|---|---|---|

| FG-K2R | Football | 4.5 | 023 |

| FG-F09 | Flat end tape | 8 | 016 |

| FG-M3 | Round end taper | 8 | 016 |

| FG-M31 | Round end taper | 8 | 018 |

Common Product Specifications

| Material | Usage | Speed |

|---|---|---|

| Tungsten Carbide | Cutting, grinding, shaping | 8,000-30,000rpm |

Product Manufacturing Process

The manufacturing of dental tungsten carbide burs involves a process known as sintering. This technique involves combining tungsten with carbon atoms, resulting in a compound renowned for hardness and wear resistance. During manufacturing, tungsten carbide is often mixed with cobalt to enhance durability and performance. The process includes compressing and heating the powdered materials to form a solid, robust product. This ensures that the burs can withstand the intensive demands of dental procedures. The structure created through sintering is dense and extremely hard, making it ideal for precision tasks in dentistry. Conclusively, this advanced technique allows for the creation of instruments that offer impeccable reliability and functionality for dental professionals.

Product Application Scenarios

Dental tungsten carbide burs are versatile tools used across various fields of dentistry, including restorative dentistry, endodontics, prosthodontics, and oral surgery. In restorative dentistry, they excel in removing old fillings, shaping cavities, and finishing restorations. Endodontic procedures utilize these burs for cleaning and shaping root canals, while in prosthodontics, they are essential for crown preparation and trimming prosthetic materials. Oral surgeons also rely on these burs for precise bone and tooth cuts during extractions and surgeries. Conclusion: Their extensive application spectrum highlights their significance in enhancing procedural efficiency and patient outcomes in dental practices worldwide.

Product After-sales Service

We offer comprehensive after-sales support, ensuring that our wholesale dental tungsten carbide burs meet your standards. Our dedicated customer service team is available 24/7 to address any quality concerns and provide technical support. We guarantee product replacement for any defects encountered within the warranty period, demonstrating our commitment to quality and customer satisfaction.

Product Transportation

The delivery of dental tungsten carbide burs is facilitated by our long-term partnerships with logistics providers like DHL, TNT, and FedEx. We ensure prompt delivery within 3-7 working days, with careful packaging to prevent damage during transit.

Product Advantages

- Durability: Made from high-quality tungsten carbide for long-lasting performance.

- Precision: Offers superior cutting efficiency for intricate dental procedures.

- Cost-effective: While initially higher in cost, their longevity provides great value over time.

- Versatility: Suitable for a wide range of dental applications.

- Patient Comfort: Reduces chair time and enhances patient experience through efficient procedures.

Product FAQ

- What makes tungsten carbide burs better than steel? Tungsten carbide burs are far superior to steel due to their hardness and wear resistance, maintaining sharpness for longer periods, thus making them more cost-effective and efficient.

- Can these burs be used for all dental procedures? Yes, they are versatile and ideal for a wide range of procedures including restorative dentistry, endodontics, and oral surgery.

- What speeds should these burs operate at? The recommended rotary speed ranges from 8,000 to 30,000 rpm, adjusting based on the material being worked on.

- Are these burs compatible with standard dental equipment? Yes, they are designed to fit standard dental handpieces and tools, both electric and pneumatic.

- How are these burs sterilized? They can withstand high temperatures and are compatible with standard sterilization procedures to ensure hygiene and safety.

- What makes them cost-effective? Despite a higher initial cost, their durability and performance reduce the need for frequent replacements, offering better value over time.

- How does tungsten carbide reduce patient discomfort? They require less pressure during use, minimizing heat buildup and reducing procedure time, enhancing patient comfort.

- Do these burs work on metals and ceramics? Yes, they are highly effective on a variety of materials, including metals and ceramics, due to their robust, sharp edges.

- What are the recommended storage conditions? Store them in a dry, cool environment away from corrosive substances to maintain their integrity.

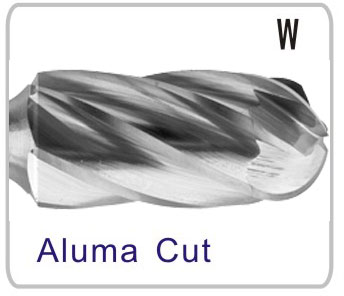

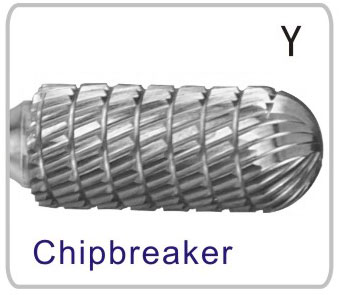

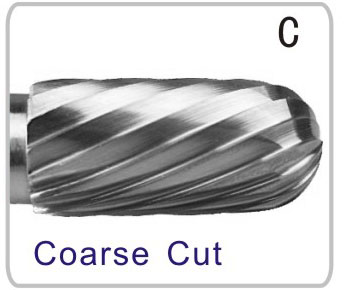

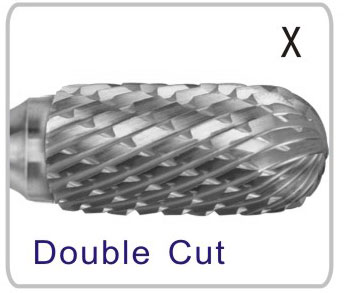

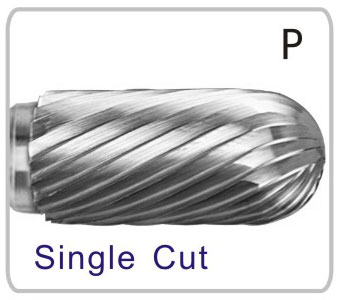

- Are there different shapes available? Yes, various shapes cater to distinct dental applications, such as round, pear, and fissure types.

Product Hot Topics

- Reliability of Wholesale Dental Tungsten Carbide Burs: The reliability of our wholesale dental tungsten carbide burs is unmatched, offering consistent performance in diverse dental applications. Known for their superior durability and precision, these burs provide exceptional value for dental professionals. Their ability to withstand rigorous procedures while maintaining sharpness ensures they remain a trusted tool in dental health care.

- Innovations in Tungsten Carbide Burs: Our commitment to innovation in the field of dental tungsten carbide burs is evident in our product line. We focus on leveraging advanced manufacturing techniques to produce robust tools that cater to the evolving needs of dental professionals. This dedication ensures we deliver instruments that enhance procedural efficiency, benefiting both professionals and patients alike.

Image Description